As industries continue to evolve in response to sustainability demands and technological advancements, the significance of Carbon Steel Plate Coil cannot be overstated. This versatile material plays a crucial role in various sectors, including construction, automotive, and manufacturing, due to its exceptional strength, durability, and cost-effectiveness. Looking ahead to 2025, it becomes essential to understand the key trends that are shaping the future of Carbon Steel Plate Coil production and application.

In this exploration, we will delve into the innovations and developments projected to influence the market, including advancements in manufacturing processes, sustainability practices, and emerging applications. The constant interplay between market demands and technological breakthroughs suggests a dynamic environment for Carbon Steel Plate Coil producers and consumers alike. By staying informed about these trends, stakeholders can position themselves effectively to leverage the potential of this indispensable material, ensuring that they keep pace with industry changes and meet evolving consumer expectations.

The carbon steel plate coil industry is poised for significant transformations as we approach 2025. According to recent market analysis, the global carbon steel market is expected to grow at a CAGR of approximately 4.1% during the forecast period. This growth can be attributed to the increasing demand from various sectors, including construction, automotive, and machinery manufacturing. Notably, the resurgence of infrastructure projects, particularly in emerging economies, is driving the need for robust and versatile materials like carbon steel plate coils.

In addition to demand dynamics, the industry is witnessing technological advancements that will shape production processes. Innovations in manufacturing techniques, such as advanced cutting technologies and automation, not only enhance efficiency but also improve the quality of the finished products. Data indicates that manufacturers are investing significantly in R&D to develop high-strength and lightweight carbon steel variants, which cater to evolving end-user requirements. Furthermore, sustainability initiatives are becoming increasingly prominent, with companies focusing on more eco-friendly production methods to minimize their carbon footprint. As we look forward to 2025, the combination of strong demand, technological evolution, and sustainability efforts will be key drivers in the carbon steel plate coil industry.

As we move toward 2025, the carbon steel plate coil industry is experiencing a transformative phase driven by emerging technologies that are shaping production processes. Innovations in manufacturing, particularly the rise of automation and artificial intelligence, are revolutionizing how steel is produced. According to a recent report by the World Steel Association, the implementation of AI in steel production can lead to efficiency improvements of up to 25%, significantly reducing waste and lowering energy consumption.

Another noteworthy trend is the integration of advanced materials science, which is paving the way for enhanced properties of carbon steel. Techniques such as alloying with micro-alloys and advancements in heat treatment processes are expected to improve the mechanical properties of steel, making it more durable and versatile for a variety of applications. The Global Carbon Steel Market Report indicates that these innovations not only cater to the increasing demand for high-quality steel but also align with sustainability goals, as improved production methods can result in a decrease in carbon emissions by approximately 30% per ton of steel produced.

Furthermore, digital twins and IoT technologies are being harnessed for real-time monitoring and predictive maintenance in steel manufacturing. These technologies enable manufacturers to optimize operations, foresee machine failures, and ensure product quality, ultimately streamlining the production process. With the projected growth of the carbon steel market anticipated to reach 1.8 billion tons by 2025, the role of these emerging technologies will be critical in meeting demands while adhering to the industry's environmental commitments.

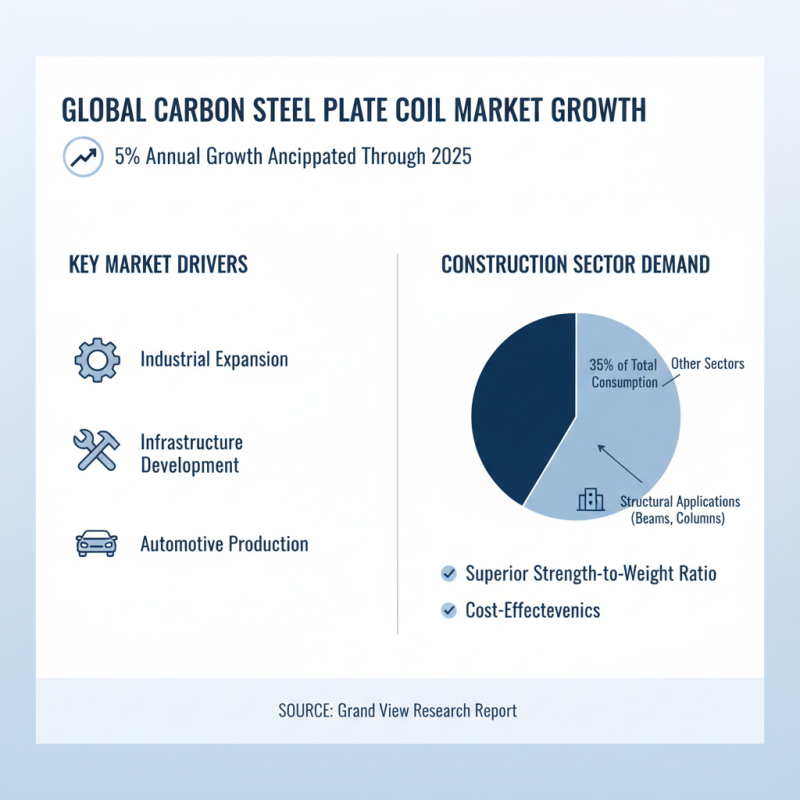

The demand for carbon steel plate coil is anticipated to surge by 5% annually through 2025, driven by various market dynamics. According to a recent report by Grand View Research, the construction sector remains a significant contributor, accounting for approximately 35% of the total consumption of carbon steel plate coil. This is largely due to the material's superior strength-to-weight ratio and cost-effectiveness, making it an ideal choice for structural applications, including beams and columns in commercial and residential buildings.

Moreover, the automotive industry is poised for considerable growth, with carbon steel plate coil being essential for manufacturing vehicle components. A report by MarketsandMarkets predicts that the automotive sector will drive a 7% increase in carbon steel demand, as manufacturers increasingly prioritize lightweight materials to enhance fuel efficiency and reduce emissions. Additionally, the surge in renewable energy projects, particularly in wind and solar, is further propelling the demand for carbon steel plate coil, since it is frequently utilized in the fabrication of wind turbine components and mounting structures. As these industries evolve, the carbon steel plate coil market must adapt to meet the forthcoming challenges and opportunities in 2025 and beyond.

As we approach 2025, sustainability practices are increasingly at the forefront of the carbon steel industry. A recent report by the World Steel Association highlighted that around 23% of global steel production is now derived from recycled materials, a significant increase from previous years. This shift towards recycling not only reduces raw material consumption but also minimizes waste and energy usage—aligning with circular economy principles. Companies are now investing heavily in electric arc furnaces, which can efficiently recycle scrap steel, producing lower emissions compared to traditional blast furnace methods.

Moreover, sustainability in the carbon steel sector extends beyond production techniques. The focus on supply chain transparency is becoming pivotal as manufacturers prioritize sourcing materials from responsible suppliers. According to a study by McKinsey & Company, 70% of steel producers are adopting more rigorous sustainability assessments that include environmental impact evaluations of raw material suppliers. This evolution reflects not just regulatory pressures but also increasing demand from consumers who are more environmentally aware.

As these practices unfold, the carbon steel industry stands on the brink of significant transformation that not only reduces its environmental footprint but also enhances its competitiveness in a more sustainable marketplace.

The applications of carbon steel plate coils are set to evolve significantly across various sectors by 2025, driven by technological advancements and a growing emphasis on sustainability. In the construction industry, for instance, carbon steel plate coils are increasingly being utilized for their high strength-to-weight ratio, which allows for more efficient structural designs. Innovations such as corrosion-resistant coatings are enhancing their longevity and performance, enabling architects and engineers to create more resilient buildings while reducing material waste.

Additionally, the automotive sector is seeing a shift towards integrating carbon steel plate coils into lightweight vehicle designs. The rise of electric vehicles necessitates materials that not only meet stringent safety standards but also contribute to energy efficiency. Consequently, manufacturers are exploring advanced processing techniques that improve ductility and formability, making it easier to mold these materials into complex shapes without compromising their integrity. As the industry moves towards greener manufacturing processes, the demand for carbon steel coil products that can be recycled and repurposed will also increase, aligning with broader environmental goals.