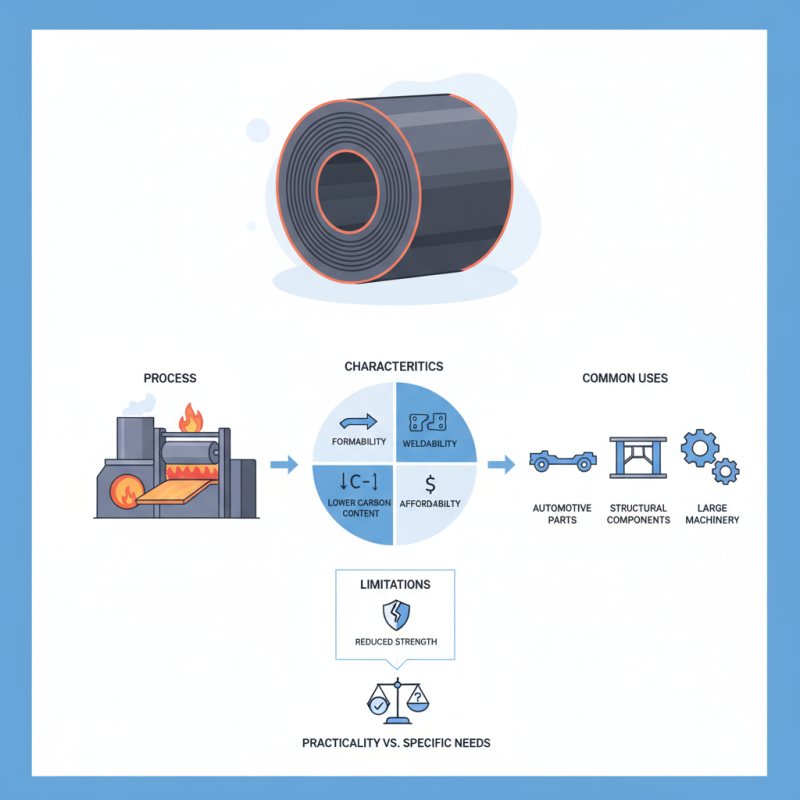

Hot Rolled Low Carbon Steel Coil is a versatile material widely used in manufacturing and construction. This type of steel boasts excellent formability and weldability. It has a lower carbon content, making it easier to shape. Industries utilize it for fabricating various products.

Common applications include automotive parts, structural components, and large machinery. The coils are produced through a process that involves heating steel and rolling it into sheets. This process gives it unique qualities. However, some might overlook potential drawbacks, such as reduced strength compared to higher carbon steels.

Despite these limitations, Hot Rolled Low Carbon Steel Coil remains a popular choice. Its affordability and availability make it appealing for many projects. The material combines practicality with efficiency, yet it is essential to evaluate specific needs before choosing it.

Hot rolled low carbon steel coil is a type of steel that undergoes a heating and rolling process. This method involves heating steel above its recrystallization temperature. The result is a flat, flexible product with a smooth finish. The low carbon content allows for improved formability. It is easy to manipulate into various shapes.

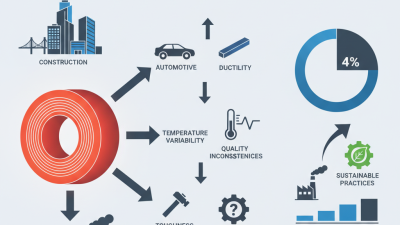

This material is widely used in construction and automotive industries. Its strength and ductility make it suitable for building structures and automotive frame parts. Additionally, hot rolled low carbon steel coil can be found in household items like furniture and appliances. Its versatility is clear, but it comes with drawbacks.

For instance, the surface finish may have imperfections. These surface defects can affect the aesthetic quality in certain applications.

Moreover, while hot rolled coils are easier to work with, they can be less precise than cold rolled types. It is essential to consider the specific application when choosing the steel type. Sometimes, engineers face challenges in balancing cost and quality. Thus, each project may demand careful evaluation to ensure the best outcome is achieved.

Hot rolled low carbon steel coil is produced through a dynamic manufacturing process. The production begins with heating steel slabs to high temperatures, typically around 1,700°F. This process allows the steel to become malleable, facilitating easier shaping. The slab is then passed through a series of rollers that reduce its thickness. This method introduces a unique grain structure, providing strength and flexibility.

Professionals in the industry report that hot rolled low carbon steel coils typically contain carbon levels around 0.05% to 0.25%. This low-carbon content results in enhanced ductility, making it adaptable for various applications. These coils are widely used in the automotive industry, construction, and machinery fabrications. However, it’s worth mentioning that the surface finish can be rough and may require further processing if aesthetics are a priority.

Despite its popularity, there are challenges. The tolerance levels for thickness may not always meet precise specifications. Customers often need to account for these variances in their projects. Additionally, the production process can lead to inconsistent mechanical properties. As demand increases, achieving uniform quality becomes crucial, yet it poses difficulties for manufacturers. Balancing efficiency with quality is an ongoing struggle.

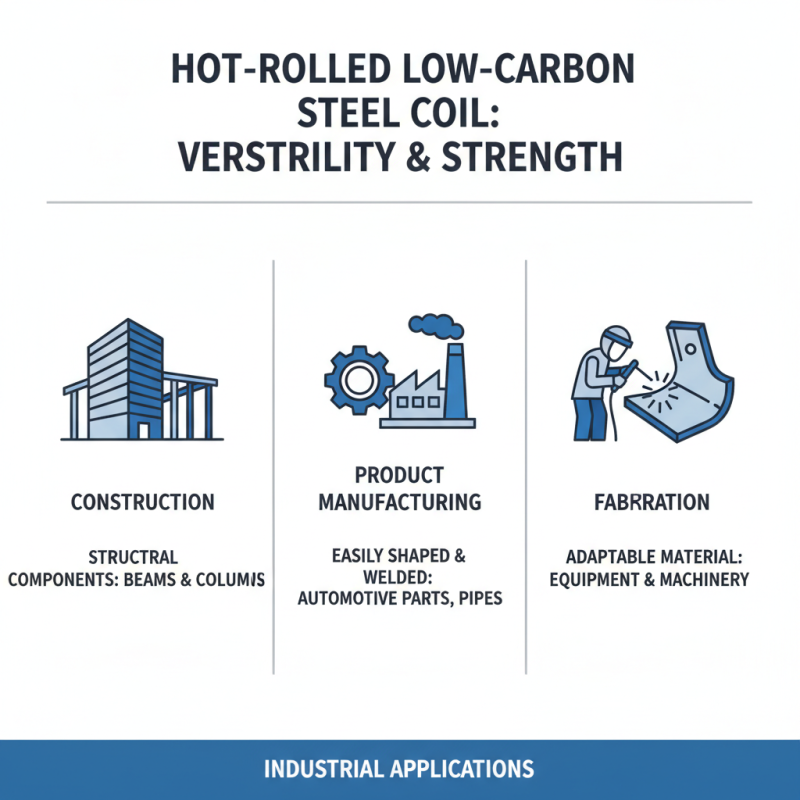

Hot rolled low carbon steel coil is a popular choice in various industries. This material has several key properties that make it suitable for diverse applications. One significant characteristic is its excellent formability. It can be easily shaped during the manufacturing process. This property is crucial for industries like automotive and construction, where intricate designs are often necessary.

Another essential feature is its good weldability. Hot rolled low carbon steel coil can be welded without special precautions. This quality is vital for creating strong joints in structures and machinery. The American Iron and Steel Institute notes that low carbon steel accounts for approximately 90% of total steel production, highlighting its prevalence and importance.

Additionally, this steel exhibits relatively lower strength compared to other high-carbon steels. However, such a trait allows for better ductility and malleability. The Trade Institute reports that the demand for low carbon steel is projected to grow by 4% annually. This expected growth calls for continuous improvement in quality and performance in response to evolving industry needs. The journey ahead may include overcoming production inconsistencies and enhancing cost-efficiency.

Hot rolled low carbon steel coil is widely used across various industries due to its versatility and strength. This type of steel is favored for making structural components in construction projects. Its ability to be easily shaped and welded makes it ideal for beams and columns. Many fabricators rely on it for product manufacturing.

Automotive industries benefit greatly from hot rolled low carbon steel coils. They use this material for parts like chassis and frames. The malleability of low carbon steel allows for intricate designs, which is essential in car manufacturing. This type of steel also finds its way into appliances like washing machines and refrigerators.

However, there are challenges with hot rolled low carbon steel. Its surface can be rough, requiring additional processing. Some industries may prefer a smoother finish. This leads to increased production time and cost. Understanding these limitations is crucial for manufacturers aiming for efficiency.

Hot rolled low carbon steel coil is a versatile material. It offers several advantages. The low carbon content makes it highly ductile. This allows for easy shaping and forming. It is often used in construction and automotive applications.

There are, however, disadvantages. The surface finish may not be as smooth as cold rolled options. Additionally, hot rolled steel can have a higher tolerance for imperfections. This may affect projects that require precise dimensions. It’s important to assess the specific needs before using it.

Tip: Check the thickness of the coil before purchasing. Thicker coils may be harder to work with. Also, consider the environmental factors as hot rolled low carbon steel is prone to rusting if not treated properly.

Another point to consider is how hot rolled steel interacts with other materials. It can weld well but may not bond smoothly with some plastics or composites. This could lead to unexpected challenges. Always test before committing to a large project.

| Property | Details |

|---|---|

| Material Type | Low Carbon Steel |

| Thickness Range | 1.2 mm to 25 mm |

| Width Range | 600 mm to 1500 mm |

| Common Uses | Automotive components, construction, shipbuilding |

| Advantages | Cost-effective, good ductility, easily processed |

| Disadvantages | Lower corrosion resistance, surface imperfections |

| Thermal Treatment | Can be heat-treated for better strength |

| Environmental Impact | Recyclable, lower emissions during production |