In the rapidly evolving landscape of modern construction, the significance of materials that offer both strength and versatility cannot be overstated. Among these, Hot Rolled Low Carbon Steel Coil has emerged as a critical component, thanks to its excellent weldability and formability. According to the World Steel Association, the demand for steel in construction is projected to increase by 1.7% annually through 2025, with low carbon steel coils playing a pivotal role in this growth due to their lightweight properties and cost-effectiveness. Moreover, the American Iron and Steel Institute reports that using low carbon steel in structural applications can lead to enhanced sustainability, as it allows for significant reductions in greenhouse gas emissions when compared to traditional alternatives. This article will explore the myriad advantages of Hot Rolled Low Carbon Steel Coil, illustrating its essential role in meeting the demands of contemporary building projects while also promoting environmentally responsible construction practices.

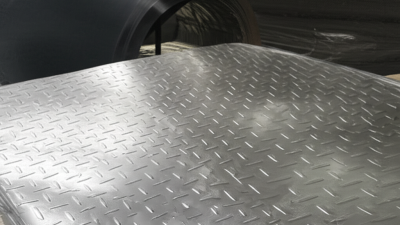

Hot rolled low carbon steel coil is an essential material in modern construction, favored for its unique composition and versatile properties. Comprising primarily iron, with a carbon content usually not exceeding 0.25%, this type of steel exhibits excellent ductility and weldability. The low carbon content allows for easy forming and shaping, making it ideal for a variety of construction applications, from structural components to automotive parts.

The hot rolling process enhances these attributes further by producing a uniform thickness and refined microstructure. This results in improved mechanical properties such as increased strength and toughness. Additionally, the surface finish achieved during hot rolling can promote better adhesion in coatings, which is crucial for enhancing durability against environmental factors. These characteristics make hot rolled low carbon steel coil not only a cost-effective choice but also a reliable option in the construction and manufacturing sectors.

Hot rolled low carbon steel coil is redefining the landscape of modern construction with its unique set of advantages. One of the primary benefits is its excellent formability, which allows for easy manipulation into various shapes and sizes. According to the American Iron and Steel Institute, hot rolled steel accounts for approximately 70% of the total steel production in the U.S., highlighting its widespread application in beams, columns, and sheet piles. The intrinsic properties of low carbon steel, including high ductility and toughness, make it ideal for structures that are frequently subjected to dynamic loads, such as bridges and high-rise buildings.

Hot rolled low carbon steel coil is redefining the landscape of modern construction with its unique set of advantages. One of the primary benefits is its excellent formability, which allows for easy manipulation into various shapes and sizes. According to the American Iron and Steel Institute, hot rolled steel accounts for approximately 70% of the total steel production in the U.S., highlighting its widespread application in beams, columns, and sheet piles. The intrinsic properties of low carbon steel, including high ductility and toughness, make it ideal for structures that are frequently subjected to dynamic loads, such as bridges and high-rise buildings.

Tip: When selecting materials for your construction project, consider hot rolled low carbon steel for its cost-effectiveness and durability. Its superior weldability can also enhance construction efficiency, as it allows for rapid assembly and modification on-site.

Another significant advantage is its favorable cost-performance ratio. The production process of hot rolled steel generally results in lower material costs compared to cold rolled alternatives, enabling builders to allocate budgets more efficiently. A report by the World Steel Association indicates that the use of hot rolled low carbon steel can lead to a reduction in overall project costs by up to 15%. This economic benefit, combined with its versatility and strength, makes it a top choice for contemporary construction needs.

Tip: Always evaluate the specific requirements of your project to leverage hot rolled low carbon steel's unique benefits while adhering to safety regulations and standards.

Hot rolled low carbon steel coil has become an essential material in modern construction projects due to its versatility and strength. This type of steel is extensively used in structural frameworks, roofing systems, and exterior facades, owing to its ability to withstand significant loads while being easily manipulated into various shapes. Its excellent weldability also makes it ideal for constructing complex geometries, ensuring that builders can achieve their design aspirations without compromising structural integrity.

Hot rolled low carbon steel coil has become an essential material in modern construction projects due to its versatility and strength. This type of steel is extensively used in structural frameworks, roofing systems, and exterior facades, owing to its ability to withstand significant loads while being easily manipulated into various shapes. Its excellent weldability also makes it ideal for constructing complex geometries, ensuring that builders can achieve their design aspirations without compromising structural integrity.

Tips: When working with hot rolled low carbon steel, it's crucial to select the right thickness and coil weight for your specific project needs. Consulting with a structural engineer can help ensure that the material chosen meets safety standards while optimizing costs. Additionally, proper storage and handling are vital to prevent rust and other surface damages, which can affect both the aesthetics and longevity of the steel.

This steel type is particularly beneficial in seismic areas, as it provides the ductility required for structures to absorb and dissipate energy during an earthquake. Furthermore, its cost-effectiveness makes it an attractive option for budget-conscious projects, allowing builders to use high-quality materials without overshooting their financial limits. Embracing hot rolled low carbon steel in modern building projects is a step towards more resilient and sustainable construction.

When comparing hot rolled and cold rolled steel for construction applications, it's essential to understand their distinct characteristics.

Hot rolled steel coils are produced at high temperatures, making them easier to shape and form.

This process gives them a rougher surface finish but enhances ductility, allowing for practical applications

in structural components where strength and flexibility are crucial.

On the other hand, cold rolled steel undergoes further processing at room temperature, resulting in a smooth surface and higher strength,

but it may not be suitable for all structural uses.

Tip: When selecting steel for your construction project,

consider the specific requirements of your application. If flexibility and weight are prioritized,

hot rolled low carbon steel may be the ideal choice. However, for projects requiring precise dimensions and a

polished finish, cold rolled steel might be more appropriate.

In modern construction, the choice between these two steel types can significantly affect both the performance

and the cost-efficiency of a project. While hot rolled steel is often favored for its affordability and ease of use

in large-scale structural applications, cold rolled steel is typically chosen for applications demanding greater

dimensional accuracy or a decorative finish. Ultimately, understanding these differences can lead to better decision-making

and optimized construction outcomes.

Tip: Always consult with a materials engineer or

structural designer who can provide insights tailored to your specific project needs.

Hot rolled low carbon steel coils are increasingly becoming a preferred choice in modern construction applications, primarily due to their sustainability and cost-effectiveness. This type of steel offers several environmental advantages over other materials. For instance, low carbon steel is highly recyclable, allowing construction projects to minimize their waste footprint by reusing materials.

Furthermore, the production processes involved in creating low carbon steel generally consume less energy compared to other steel types, reducing the overall carbon emissions associated with construction.

From a financial perspective, utilizing hot rolled low carbon steel coils can significantly lower project costs. These materials are not only readily available and affordable but also conducive to efficient fabrication and installation. The inherent ductility and strength of low carbon steel mean that it can be employed in various structural applications, thereby reducing the need for additional materials and labor. As construction industries explore more sustainable practices, incorporating low carbon steel into building designs not only meets environmental standards but also paves the way for better budget management and long-term savings.