Hot Rolled Low Carbon Steel Coil is a versatile material with numerous applications. Its unique properties make it suitable for various industries. This steel type is known for its ease of fabrication and good weldability.

Manufacturers favor Hot Rolled Low Carbon Steel Coil for its strength and durability. It provides an excellent balance between cost and performance. This coil is often used in the automotive, construction, and machinery sectors. Yet, there are challenges. The finished surface may require treatment to enhance its appearance and protect against rust.

Understanding the benefits and applications of Hot Rolled Low Carbon Steel Coil is crucial. It allows businesses to make informed decisions. However, it’s important to reflect on how different settings can require tailored solutions. Each application may present unique demands and limitations that should be carefully considered.

Hot rolled low carbon steel coils are widely used in various industries due to their remarkable properties. These coils are produced through a process of rolling steel at elevated temperatures. This method allows for better flexibility and ductility. The finished product is often used for structural applications. It can be found in buildings, bridges, and machinery.

One of the key benefits of hot rolled low carbon steel coils is their cost-effectiveness. They require less processing compared to other types of steel. This leads to lower production costs and faster turnaround times. Additionally, their ease of manipulation makes them favorable for manufacturing purposes. They can be cut, shaped, and welded without significant complications.

However, relying solely on this steel type has its drawbacks. Hot rolled steel can have a rough surface, which may not be ideal for aesthetic purposes. It may also have lower strength compared to cold worked variants. Users should weigh these factors carefully before making a decision. Understanding the specific application needs is crucial in selecting the right materials.

| Dimension | Value |

|---|---|

| Thickness (mm) | 1.0 - 12.0 |

| Width (mm) | 600 - 2000 |

| Yield Strength (MPa) | 250 - 350 |

| Tensile Strength (MPa) | 400 - 500 |

| Elongation (%) | 20 - 30 |

| Density (g/cm³) | 7.85 |

| Thermal Conductivity (W/m·K) | 50.2 |

| Common Applications | Automotive, Construction, Machinery |

Hot rolled low carbon steel coils have become increasingly popular in various industries. Their flexibility and malleability make them ideal for a wide range of applications. The low carbon content provides enhanced ductility and excellent weldability, which are crucial in construction and manufacturing sectors.

One key benefit is their cost-effectiveness. Industry reports indicate that low carbon steel coils can reduce production costs by up to 20%. This affordability makes them appealing for producing parts in automotive, machinery, and even household appliances. Additionally, their environmental impact is worth noting; hot rolled low carbon steel can be recycled multiple times without losing quality.

Tips: Always check the material specifications. Ensure the steel coil meets the required standards for your application. Regular maintenance and inspection can extend the product's lifespan.

Another important aspect is their thermal properties. Hot rolled low carbon steel coils can withstand high temperatures. This feature is critical in industries such as oil and gas, where temperature control is vital. However, one must be cautious with their corrosion resistance. These coils typically require protective coatings to enhance durability in harsh environments.

Tips: Consider the coating options available. Proper surface treatment can prevent rust and degradation. Regular upkeep is essential to maintain structural integrity over time.

Hot rolled low carbon steel coils are widely used across various industries. Their versatility makes them ideal for a range of applications. In construction, they serve as reinforcement materials in concrete structures. Builders appreciate their strength and flexibility. These coils help improve structural integrity in many projects. They can be easily shaped and welded to fit specific needs.

In the automotive sector, hot rolled low carbon steel is essential. It forms parts like chassis, frames, and panels. The material’s ductility allows for complex shapes. This is crucial for minimizing weight while maintaining safety. However, quality control remains a concern in this area. Variations in thickness can lead to challenges during manufacturing.

Manufacturers in the appliance industry also rely on these coils. Products such as refrigerators and ovens often use this material. The coil's surface finish is vital for aesthetics and durability. Yet, achieving a consistent finish can be tricky. This inconsistency may affect customer satisfaction. Hot rolled low carbon steel coils undoubtedly provide numerous benefits. Yet, attention to detail in production is crucial for optimizing their use across these applications.

This chart displays the common applications of hot rolled low carbon steel coils across various industries, showcasing their versatility and importance.

Hot rolled low carbon steel coils are widely used in various sectors. They are known for their excellent formability and weldability. Compared to other steel types, such as high carbon steel or stainless steel, low carbon steel offers more flexibility. This flexibility makes it suitable for numerous applications, from automotive components to structural frameworks. Research shows that low carbon steel can achieve a tensile strength of around 370 MPa, making it versatile for different manufacturing needs.

When comparing low carbon steel to alloys, some distinct differences emerge. Alloys often provide enhanced corrosion resistance or higher strength. Yet, the cost of alloys can be significantly higher. For example, low carbon steel costs approximately $700 per ton, while some alloys exceed $1,500 per ton. This cost disparity influences material selection for projects, especially when budgets are tight.

However, the benefits of low carbon steel are not without limitations. Its lower strength compared to higher-grade alloys can be a drawback in demanding environments. Sometimes, low carbon steel can be susceptible to deformation under high stress. This vulnerability leads engineers to reconsider material choices for critical applications. It raises questions about the proper use of steel types and informs decisions in production processes.

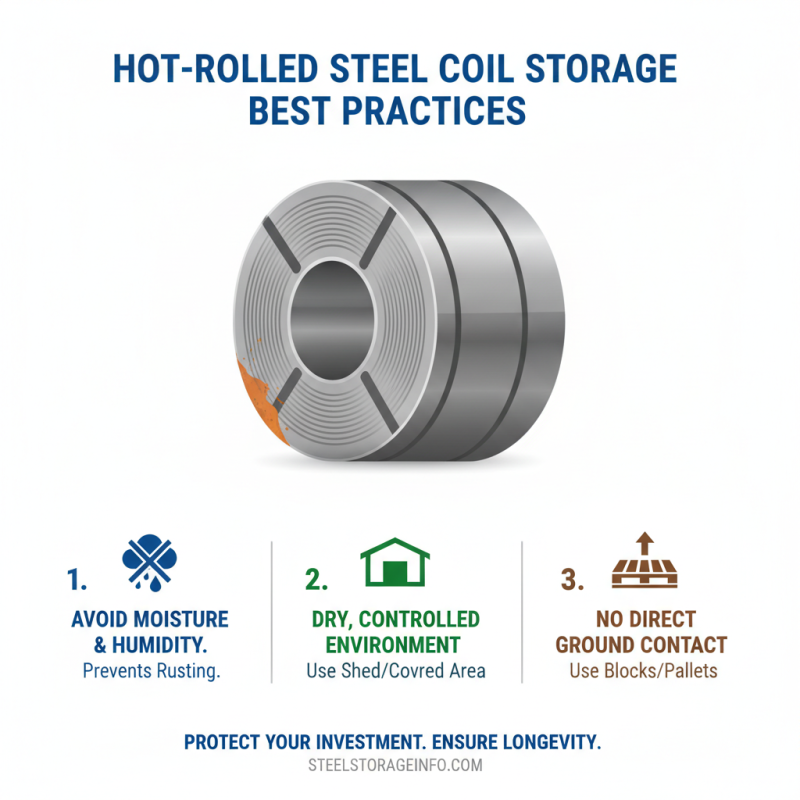

When it comes to hot rolled low carbon steel coils, proper storage and handling are crucial. These coils are sensitive to environmental factors. Moisture and humidity can lead to rusting. Therefore, it’s essential to store them in a dry, controlled environment. A simple shed or covered area can provide protection. Avoid direct contact with the ground to minimize moisture exposure.

Here are some tips for effective storage:

- Use wooden pallets to elevate the coils.

- Cover the coils with tarps or protective sheeting.

- Regularly check for signs of rust or damage.

Handling these coils requires care. The weight of the coils makes them difficult to maneuver. Proper equipment is necessary. Using forklifts with padded forks prevents damage. Also, operators must wear protective gear. Safety should always be a priority.

It’s important to reflect on mistakes. Sometimes, coils get scratched during handling. This can be avoided with better techniques. Also, not keeping an inventory can lead to confusion when retrieving coils. Organizing storage spaces can greatly enhance efficiency.

By following these practices, you can ensure the longevity and quality of hot rolled low carbon steel coils.