In the world of manufacturing, materials play a crucial role in determining the quality and durability of the final products. One such material that has gained significant traction is Hot Rolled Carbon Steel Coil. This versatile and economically favorable steel variant is extensively used in various industries, including construction, automotive, and appliance manufacturing. According to Dr. Emily Carter, a renowned expert in metallurgy, "The adoption of Hot Rolled Carbon Steel Coil has revolutionized manufacturing processes by offering a perfect blend of strength and malleability."

The advantages of Hot Rolled Carbon Steel Coil cannot be overstated. Its ability to be easily formed into different shapes while retaining strength makes it an invaluable asset for manufacturers. Additionally, the hot rolling process enhances its properties, resulting in improved mechanical performance, which is essential for the rigorous demands of production environments. By understanding the benefits of this type of steel, manufacturers can make informed decisions that enhance their operational efficiency and product longevity.

As industries continue to innovate and seek materials that provide both quality and cost-effectiveness, Hot Rolled Carbon Steel Coil stands out as a preferred choice. This article delves deeper into what Hot Rolled Carbon Steel Coil is, its advantages in manufacturing, and its impact on various applications.

Hot rolled carbon steel coil is a crucial material widely used in various manufacturing sectors due to its unique properties and production advantages. The process of hot rolling involves heating steel above its recrystallization temperature, which allows it to be easily shaped and formed. This method produces coils that are thicker and have a rough surface finish, making them ideal for applications where strength and durability are prioritized. The resulting product not only has excellent structural integrity but also exhibits enhanced flexibility, making it easier for manufacturers to work with during fabrication processes.

One of the primary benefits of hot rolled carbon steel coil is its cost-effectiveness. The hot rolling process requires less energy than cold rolling, resulting in lower production costs. Furthermore, manufacturers can produce larger volumes more rapidly, enabling them to meet higher demands while maintaining efficiency. The versatility of hot rolled coils allows them to be used in a broad range of applications, including automotive components, construction materials, and equipment manufacturing. With its combination of strength, malleability, and affordability, hot rolled carbon steel coil remains a fundamental choice for manufacturers looking to optimize their production capabilities.

The manufacturing process of hot rolled carbon steel coil begins with heating steel billets to a temperature above their recrystallization point. This high-temperature treatment allows the material to be easily shaped and formed. Typically, the steel is heated to around 1,700°F (about 926°C), which makes it malleable enough for rolling. Once it reaches this temperature, the steel is passed through a series of rollers that reduce its thickness and reshape it into coils. The hot rolling process not only enhances the strength of the steel but also improves its ductility, making it suitable for various manufacturing applications.

Moreover, the hot rolling process is beneficial in producing uniform thickness and desired surface finish. The American Iron and Steel Institute (AISI) reports that approximately 90% of the steel produced in the U.S. is hot-rolled, highlighting its critical role in the industry. This method is particularly favored for projects that require strong structural qualities, such as beams, automotive frames, and various construction applications.

Tips: When working with hot rolled carbon steel coils, always ensure proper handling and storage to prevent surface damage. Additionally, consider the specific requirements of your application—such as tensile strength and formability—when choosing the thickness and grade of the steel. Understanding these factors can significantly enhance performance and cost-effectiveness in manufacturing processes.

Hot rolled carbon steel coils are widely recognized for their essential role in various manufacturing processes due to their unique characteristics. One of the primary features is the high-temperature processing, which allows the steel to be shaped and formed more easily compared to cold-rolled steel. This process enhances ductility, enabling the material to be stretched into thin sheets without fracturing. The surface finish of hot rolled steel is typically rougher and may contain scale from the manufacturing process, but this can often be remedied in subsequent treatments.

In terms of specifications, hot rolled carbon steel coils are available in a range of thicknesses, widths, and lengths, providing flexibility for different applications. The carbon content generally varies from low to medium levels, impacting the overall strength and workability of the steel. This adaptability makes hot rolled carbon steel a preferred choice for structural applications, components, and manufacturing of steel products. Additionally, the material's ability to be easily weldable and formable contributes to its popularity in industries such as automotive, construction, and machinery manufacturing. These characteristics combined make hot rolled carbon steel coils a vital resource in modern manufacturing.

| Attribute | Details |

|---|---|

| Material Type | Carbon Steel |

| Production Process | Hot Rolling |

| Thickness Range | 1.5 mm to 25 mm |

| Width Range | 600 mm to 2000 mm |

| Tensile Strength | 350 to 700 MPa |

| Yield Strength | 220 to 500 MPa |

| Key Benefits | Cost-effective, Versatile, Good machinability |

| Common Applications | Automotive, Structural beams, Pipe manufacturing |

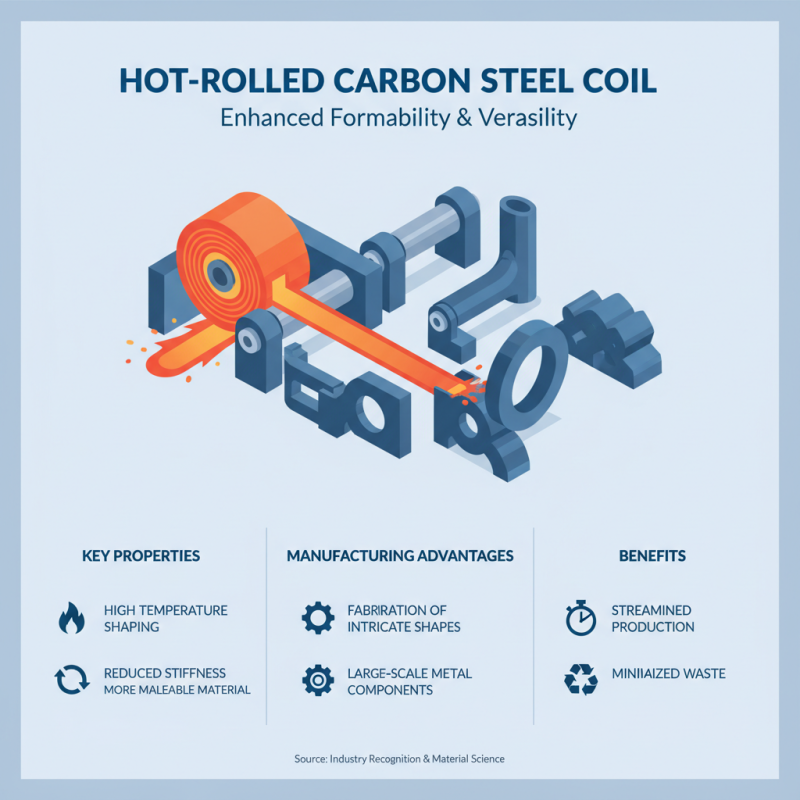

Hot rolled carbon steel coil is widely recognized in the manufacturing industry for its remarkable properties and versatility. One of the main advantages of utilizing hot rolled carbon steel is its enhanced formability. The hot rolling process allows the steel to be shaped and formed at high temperatures, which reduces stiffness and ensures a more malleable material. This property is particularly beneficial for manufacturers who require intricate shapes or large-scale metal components, as it streamlines the production process and minimizes waste.

Another significant benefit of hot rolled carbon steel is its superior mechanical properties. The material boasts high strength and durability, making it suitable for applications that demand robust performance, such as in construction and automotive industries. Hot rolled carbon steel also tends to have a finer grain structure, improving its toughness and resistance to impact. Furthermore, this type of steel often requires less processing and can be easily welded or machined, further reducing production costs and time. By incorporating hot rolled carbon steel into their operations, manufacturers can achieve both quality and efficiency, ultimately enhancing productivity.

Hot rolled carbon steel coil is a versatile material widely used across various industries due to its unique properties and cost-effectiveness. In the construction industry, for instance, this type of steel coil is favored for producing structural components, such as beams and columns, which are crucial for building stability. Its excellent strength-to-weight ratio allows for lighter constructions without compromising safety. Moreover, hot rolled carbon steel coil is often used in the manufacturing of industrial equipment and machinery, where durability and high performance are essential.

Another significant application of hot rolled carbon steel coil is in the automotive industry. Car manufacturers utilize this material for producing body panels, frames, and other critical components, benefiting from its malleability and ability to withstand deformation under stress. Additionally, in the energy sector, hot rolled carbon steel coils play an important role in fabricating pipelines and storage tanks, where they demonstrate resilience against high pressures and various environmental conditions. These applications highlight the essential role of hot rolled carbon steel coil in supporting infrastructure and technological advancements across multiple sectors.