In today's manufacturing and construction industries, the significance of selecting the right materials cannot be overstated. One such material that plays a pivotal role is the Carbon Steel Roll Coil, renowned for its versatility, strength, and cost-effectiveness. According to a report by Smithers Pira, the global market for carbon steel is projected to reach approximately $1 trillion by 2025, with the demand for carbon steel roll coils significantly influencing this growth. This is largely due to advancements in its production technology and an increase in applications across various sectors, including automotive, aerospace, and construction. Understanding the fundamental characteristics and advantages of Carbon Steel Roll Coils can empower industry professionals to make informed decisions, optimize their supply chains, and enhance overall productivity. Herein, we present seven essential facts that will equip you with the knowledge needed to leverage Carbon Steel Roll Coils for your specific industry requirements.

Carbon steel roll coils are a crucial material across various industries due to their versatile properties and composition. Comprised primarily of iron and carbon, these coils can be tailored to meet specific mechanical requirements through varying carbon content. Generally, the carbon percentage ranges from 0.05% to 2.0%, which influences hardness, ductility, and tensile strength. Lower carbon content leads to increased malleability, making it suitable for processes like welding, while higher carbon percentages result in a harder material that is more resistant to wear.

Carbon steel roll coils are a crucial material across various industries due to their versatile properties and composition. Comprised primarily of iron and carbon, these coils can be tailored to meet specific mechanical requirements through varying carbon content. Generally, the carbon percentage ranges from 0.05% to 2.0%, which influences hardness, ductility, and tensile strength. Lower carbon content leads to increased malleability, making it suitable for processes like welding, while higher carbon percentages result in a harder material that is more resistant to wear.

Understanding the composition of carbon steel roll coils also involves recognizing the impact of additional alloying elements. Elements such as manganese, silicon, and trace amounts of chromium or nickel can enhance properties like corrosion resistance and toughness. This adaptability makes carbon steel a popular choice in construction, automotive, and manufacturing sectors. Properly understanding these properties allows industries to optimize the application of carbon steel roll coils, ensuring they meet specific performance expectations and regulatory requirements.

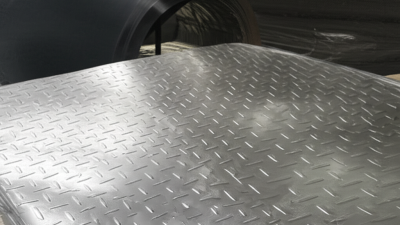

Carbon steel roll coils are increasingly recognized for their versatility and strength across various industries. One of the key advantages of using these coils is their excellent mechanical properties, which include high tensile strength and durability. This makes them ideal for applications requiring heavy-duty materials, such as construction, automotive, and manufacturing. The ability to withstand significant stress and resist deformation under load makes carbon steel roll coils a reliable choice for structural components.

Another important benefit is the cost-effectiveness of carbon steel roll coils. Compared to other materials, carbon steel offers a lower initial investment without compromising quality. This is particularly advantageous for industries where budget constraints are critical, allowing manufacturers to maximize their resources. Additionally, carbon steel can be easily processed and formed, providing flexibility in design and enabling rapid production timelines. This adaptability not only enhances efficiency but also opens up opportunities for innovative applications across diverse fields.

Carbon steel roll coils have become integral to various industries due to their versatile applications and robust properties. Commonly used in automotive manufacturing, construction, and appliances, these coils offer unparalleled strength and durability. According to a recent report by the World Steel Association, carbon steel accounts for over 90% of global steel production, reflecting its significance in industrial applications.

In the automotive sector, carbon steel roll coils are essential for producing components that require high strength-to-weight ratios. The National Highway Traffic Safety Administration reports that lightweight vehicles using high-strength steel can improve fuel efficiency by up to 20%. Furthermore, in construction, these coils are commonly utilized in structural framing and reinforced bars due to their excellent weldability and formability, ensuring safe and durable infrastructure.

**Tips:** When selecting carbon steel roll coils for your operations, consider the thickness and grade that best suits your application to optimize performance. Additionally, always check for certifications to ensure compliance with industry standards. Regularly updating your knowledge on the latest advancements in material technology can also help you choose the best options for your projects.

The quality and performance of carbon steel roll coils are critical factors that directly influence their suitability for various industrial applications. Several elements play a significant role in determining these properties, including the chemical composition of the steel, the manufacturing processes involved, and environmental conditions during production. According to a report by the American Iron and Steel Institute, the carbon content typically ranges from 0.05% to 0.25%, which significantly impacts strength, ductility, and hardness. Higher carbon content usually leads to increased strength but reduced ductility, thus affecting the coil's performance in specific applications.

Additionally, the quality of carbon steel roll coils is also influenced by the production methods, such as hot rolling or cold rolling processes. Hot-rolled coils usually feature a larger grain structure, improving flexibility but potentially reducing tensile strength compared to cold-rolled options, which boast tighter tolerances and a smoother surface finish. A study from the International Journal of Materials Science highlights that cold-rolled coils can have yield strengths exceeding 300 MPa, while hot-rolled products typically show about 250 MPa. Understanding these factors allows industries to select the appropriate carbon steel roll coils that meet their specific performance requirements and enhance their operational efficiency.

When it comes to maintaining carbon steel roll coils in industrial settings, proper care is paramount to ensure longevity and optimal performance. According to the Steel Manufacturers Association, carbon steel products account for approximately 70% of the total steel usage in the United States, highlighting the material's importance across numerous industries. Maintaining quality in carbon steel roll coils not only ensures structural integrity but also enhances productivity in manufacturing processes.

To extend the lifespan of carbon steel roll coils, regular inspections and maintenance are crucial. It is recommended to implement a routine schedule for checking for surface rust, corrosion, and any signs of wear or damage. A survey by the American Iron and Steel Institute found that regular maintenance could reduce downtime by up to 20%, significantly impacting overall operational efficiency. Furthermore, applying appropriate protective coatings can prevent oxidation and enhance the coils' resistance to harsh environmental conditions, which is essential in industries such as automotive and construction where durability is non-negotiable. Engaging in best practices for the maintenance and care of carbon steel roll coils will ensure that businesses can maximize their investment and maintain high-quality production standards.

| Fact No. | Description | Maintenance Tips | Common Uses |

|---|---|---|---|

| 1 | Carbon steel roll coils are available in various grades. | Keep coils away from moisture to prevent rust. | Used in construction and automotive industries. |

| 2 | They can be easily welded and formed. | Regularly check for signs of wear or corrosion. | Ideal for manufacturing equipment and machinery parts. |

| 3 | They provide excellent tensile strength. | Apply protective coatings when necessary. | Used in the manufacture of pipelines. |

| 4 | Carbon steel roll coils are cost-effective. | Store properly to maintain quality. | Widely used in HVAC systems. |

| 5 | They are recyclable, contributing to sustainability. | Avoid excessive exposure to chemical agents. | Used in the manufacturing of furniture. |

| 6 | Various finishes are available, including hot-rolled and cold-rolled. | Ensure proper cleaning after use to avoid buildup. | Commonly found in appliances and electronics. |

| 7 | They have a wide range of applications across industries. | Monitor temperature and humidity in storage areas. | Used in piping and structural applications. |