Selecting the appropriate Carbon Steel Plate Coil for your industrial applications is crucial for achieving optimal performance and efficiency. With the global demand for carbon steel expected to rise by 2.4% annually, reaching over 1.5 billion tons by 2025, it is vital for industries to understand the specifications and characteristics of different plate coils.

According to a recent market analysis by Grand View Research, the construction and automotive sectors are major consumers, reflecting the necessity for high-quality carbon steel materials that comply with stringent industry standards. Thicken carbon steel plate coils are favored for their durability and versatility, making them suitable for applications ranging from structural components to manufacturing processes.

By evaluating factors such as chemical composition, tensile strength, and surface treatment, industries can ensure they select the right Carbon Steel Plate Coil that meets their specific operational needs and enhances their production capabilities.

Selecting the appropriate Carbon Steel Plate Coil for your industrial applications is crucial for achieving optimal performance and efficiency. With the global demand for carbon steel expected to rise by 2.4% annually, reaching over 1.5 billion tons by 2025, it is vital for industries to understand the specifications and characteristics of different plate coils.

According to a recent market analysis by Grand View Research, the construction and automotive sectors are major consumers, reflecting the necessity for high-quality carbon steel materials that comply with stringent industry standards. Thicken carbon steel plate coils are favored for their durability and versatility, making them suitable for applications ranging from structural components to manufacturing processes.

By evaluating factors such as chemical composition, tensile strength, and surface treatment, industries can ensure they select the right Carbon Steel Plate Coil that meets their specific operational needs and enhances their production capabilities.

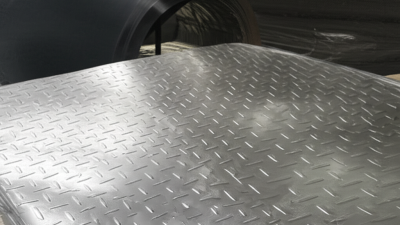

Carbon steel plate coils are critical materials in various industrial applications due to their strength, versatility, and cost-effectiveness. These coils are primarily composed of iron and carbon, with carbon content typically ranging from 0.05% to 2.0%, significantly impacting their mechanical properties. According to the American Iron and Steel Institute (AISI), carbon steel is categorized into low, medium, and high carbon steels, each serving distinct industrial purposes. Low carbon steel, with approximately 0.05%-0.3% carbon content, is favored for applications such as automotive body parts, whereas medium carbon steel, containing 0.3%-0.6% carbon, is often used in manufacturing machinery and structural components.

The industrial uses of carbon steel plate coils extend across various sectors, including construction, automotive, and shipbuilding. For instance, a report by Research and Markets forecasts that the global carbon steel market will reach USD 1 trillion by 2027, driven by increasing demand for infrastructure development and automotive manufacturing. Furthermore, carbon steel plate coils are preferred for their high formability and weldability, making them ideal for fabricating products like pipelines and pressure vessels. With ongoing advancements in manufacturing techniques, selecting the appropriate type of carbon steel plate coil tailored to specific applications will be pivotal for ensuring efficiency and durability in industrial operations.

| Property | Description | Typical Applications |

|---|---|---|

| Thickness | Typically ranges from 0.5 mm to 50 mm | Construction, Metal Fabrication |

| Width | Can vary from 1000 mm to 2000 mm | Heavy Machinery, Structural Components |

| Yield Strength | Ranges from 250 MPa to 500 MPa depending on the grade | Construction, Automotive Parts |

| Chemical Composition | Includes carbon, manganese, silicon, and other elements | Manufacturing, Steel Frames |

| Surface Finish | Can be hot-rolled, cold-rolled, or treated | Construction, High-stress Applications |

| Weight | Heavier plates may require special handling | Heavy Equipment Manufacturing |

When selecting a carbon steel plate coil for industrial applications, it’s crucial to evaluate the key attributes of strength, durability, and corrosion resistance. Strength is often the first consideration; it determines how much load the material can bear without deformation. Choose a plate with appropriate yield strength that matches the specific requirements of your project, as this will ensure structural integrity over time.

Durability is equally important, especially for applications exposed to harsh environments. Look for carbon steel plates that are manufactured with alloying elements that enhance their toughness and resistance to wear and tear. This will help your components maintain performance even in challenging conditions.

Corrosion resistance is a vital factor to consider, particularly for industries dealing with moisture, chemicals, or salty air. While carbon steel is generally susceptible to rust, certain treatments and coatings can significantly improve its resistance. Consider opting for galvanized or painted steel options, as these can provide an effective barrier against corrosion and extend the lifespan of your equipment.

**Tips:** Always consult technical datasheets when comparing materials. Additionally, consider the specifics of your application—higher corrosion resistance often comes at the cost of reduced strength, so finding the right balance is essential. Lastly, don't forget to assess the cost versus the long-term benefits; sometimes, an upfront investment in higher quality materials pays off significantly in longevity and performance.

This chart displays a comparison of the key attributes significant for selecting the right carbon steel plate coils in industrial applications. The ratings reflect the strength, durability, and corrosion resistance on a scale of 1 to 10.

When selecting a carbon steel plate coil for industrial applications, evaluating thickness and dimensions is crucial. The right thickness can affect the mechanical properties of the material, influencing its strength and durability under different load conditions. For instance, heavier applications in construction or heavy machinery may require thicker plates, while lighter applications might be better served by thinner options. Always consider the specific working environment and demands of your project to ensure optimal performance.

Tips: When determining the thickness, refer to industry standards that outline minimum requirements for various applications. Consulting with engineers or industry professionals can provide valuable insights based on real-world experience.

Dimensions also play a significant role in ensuring compatibility with existing systems and machinery. Make sure to accurately measure the area where the coil will be installed, taking into account any additional factors such as welding or joining methods that may impact the overall size. Ensuring that dimensions meet the necessary specifications will help prevent installation issues down the line.

Tips: Double-check all measurements and consider any tolerances needed for manufacturing processes to avoid discrepancies. It’s often helpful to keep communication lines open with suppliers for guidance on dimension specifications.

When selecting the appropriate carbon steel plate coil for industrial applications, understanding the different grades of carbon steel is crucial for achieving optimal performance. Carbon steel is generally categorized into three grades: low, medium, and high carbon steel.

Low carbon steel, containing up to 0.3% carbon, is known for its excellent ductility and weldability, making it ideal for applications where flexibility and shape retention are essential. This grade is commonly used in automotive manufacturing and construction materials, where large-scale shaping is required without sacrificing strength.

When selecting the appropriate carbon steel plate coil for industrial applications, understanding the different grades of carbon steel is crucial for achieving optimal performance. Carbon steel is generally categorized into three grades: low, medium, and high carbon steel.

Low carbon steel, containing up to 0.3% carbon, is known for its excellent ductility and weldability, making it ideal for applications where flexibility and shape retention are essential. This grade is commonly used in automotive manufacturing and construction materials, where large-scale shaping is required without sacrificing strength.

Medium carbon steel, with carbon content ranging from 0.3% to 0.6%, strikes a balance between strength and ductility. It is often employed in the production of heavy machinery and structural components that require both toughness and moderate wear resistance. Finally, high carbon steel, containing more than 0.6% carbon, offers superior hardness and wear resistance, making it suitable for applications such as cutting tools and high-strength wires. However, this grade can be less adaptable and may require special heat treatment processes to enhance its usability.

Understanding these distinctions allows engineers and procurement specialists to choose the right carbon steel grade that meets the specific demands of their projects.

When selecting carbon steel plate coils for industrial applications, cost considerations play a crucial role in the decision-making process. Understanding the total ownership cost is essential, which includes not only the initial purchase price but also factors like maintenance, durability, and potential waste during processing. Evaluate the quality and performance specifications of the steel plates, as lower costs may sometimes compromise the product's reliability, leading to increased expenses over time.

Supplier selection is equally important when sourcing carbon steel plate coils. A reputable supplier should offer not only competitive pricing but also consistency in quality and service. It's beneficial to assess suppliers based on their production capabilities, delivery timelines, and customer support. Additionally, establishing a long-term relationship with a supplier can lead to better pricing agreements and access to premium materials, which can significantly optimize your production processes and overall operational efficiency.