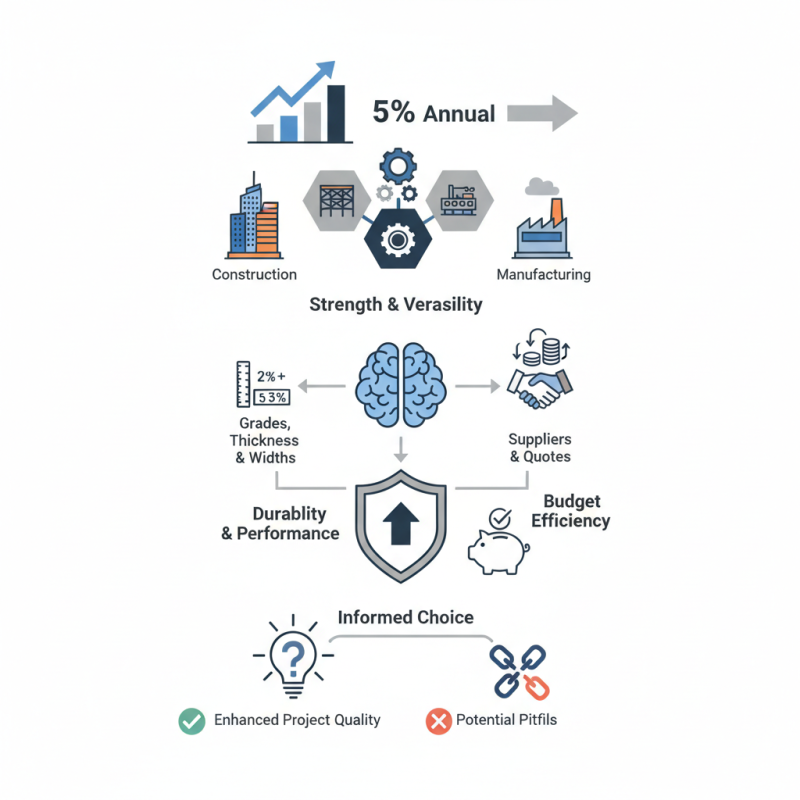

Choosing the right Carbon Steel Hot Rolled Coil is crucial for your projects. This material is favored in various industries due to its strength and versatility. According to a recent report by Steel Insights, the demand for hot rolled steel is expected to grow by 5% annually through 2025. The applications vary from construction to manufacturing, making it essential to select the correct specifications.

Industry expert, Dr. Robert Chen, states, "The choice of Carbon Steel Hot Rolled Coil impacts durability and performance." This insight underscores the importance of understanding coil grades, thickness, and widths. With so many options, decision-making can often feel overwhelming. Each project has unique requirements, and the consequences of poor selection can lead to significant setbacks.

Pricing is another factor to consider. Market fluctuations can affect costs, so it's essential to stay informed. An informed choice will not only enhance project quality but also maximize budget efficiency. Engaging with suppliers and seeking multiple quotes is advisable. But remember, not all coils are created equal. You must recognize the potential pitfalls in order to make a better choice.

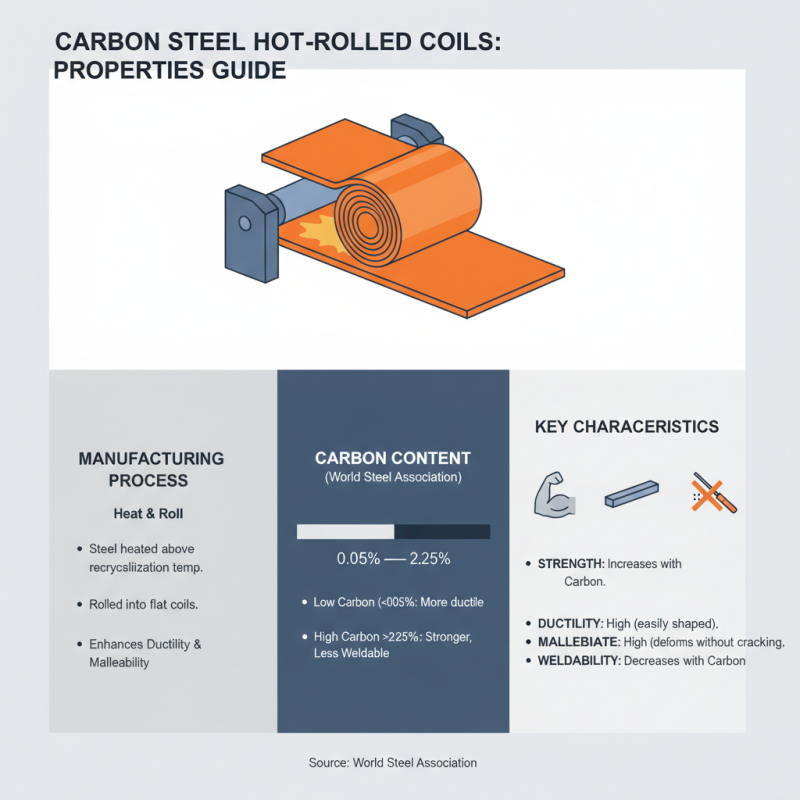

When selecting carbon steel hot rolled coils, it's essential to grasp their basic properties. These coils are made by heating steel and rolling it into flat shapes. The process enhances ductility and malleability. According to the World Steel Association, carbon content in these coils generally ranges from 0.05% to 0.25%. Higher carbon percentages lead to increased strength, but decreased weldability.

The surface finish of hot rolled coils is often rough and may include scale. This can affect subsequent machining and treatment processes. In many cases, companies overlook the need for surface preparation. About 30% of steel used in construction is composed of hot rolled products, as per recent industry reports. The choice often depends on the specific requirements of the project, such as thickness and tensile strength.

It's crucial to evaluate the coil's specifications based on intended application. Overlooking this aspect can lead to structural failures. For example, if higher strength is required, opting for a coil with lower carbon content may not suffice. Continuous improvement in understanding these factors can enhance project outcomes and reduce waste. Always consider the long-term implications when selecting materials.

When selecting carbon steel hot rolled coils, understanding their key properties is crucial. These coils are known for their superior strength and durability. They offer excellent resistance to deformation under stress. This makes them ideal for structural applications. However, the variation in quality can sometimes lead to unexpected outcomes.

Surface finish is another important aspect to consider. Hot rolled coils typically have a rough surface texture. While this is standard, it may impact the aesthetics in certain projects. Additionally, pay attention to the thickness and width specifications. Manufacturers may deliver coils that do not precisely meet your requirements. This inconsistency can challenge your project plans.

Another property worth noting is the weldability of these coils. While they can be welded, the resulting joints might not always meet expectations. It's essential to assess the compatibility with other materials. Testing before full-scale application can help identify potential issues. Embracing these complexities can lead to better decision-making in project planning.

When assessing carbon steel hot rolled coils, several critical factors demand attention.

Visual inspection is essential. Look for surface flaws or discoloration. A smooth finish indicates potential quality. However, minor imperfections often exist. These should not deter you from considering the overall material integrity.

Thickness consistency is another key indicator of quality. Reports from the American Iron and Steel Institute show that uniform thickness can enhance performance in various applications. Variations of as little as 0.01 inches can impact structural stability. This is vital for high-stress environments.

Chemical composition plays a significant role in the performance of carbon steel. The level of carbon affects hardness and ductility. Buyers should check for carbon content typically around 0.05% to 0.25%. However, exceeding these limits may reduce formability. Beyond carbon, elements like manganese and silicon enhance strength and toughness. Balancing these components is crucial for optimal performance.

Carbon steel hot rolled coils have a wide range of applications across various industries. In construction, they provide strength and durability. Structures often rely on these coils for support beams and reinforcements. They are also used in making automotive components. Car manufacturers need materials that can withstand heavy wear and tear. Carbon steel coils offer that resilience.

Another important area is manufacturing. Many factories use hot rolled coils in machinery and equipment. The coils can be easily shaped and cut into desired sizes. This versatility makes them essential in producing parts for appliances or tools. However, using carbon steel requires careful consideration. The material may corrode if not properly protected. It's crucial to think about the long-term impact on projects.

Moreover, the recycling potential of carbon steel makes it appealing. Many industries are shifting towards sustainable practices. Using recycled materials can reduce costs and waste. Still, sourcing high-quality recycled steel presents challenges. Finding a balance between quality and sustainability can be difficult. Projects may need adjustments to accommodate these factors.

Choosing carbon steel hot rolled coils involves careful consideration of costs. The price fluctuates based on various factors such as market demand, coil thickness, and quantity. Larger orders often lead to discounts. Analyzing your budget is crucial before making a decision.

Think about the intended use of the coils. If you need them for structural applications, investing a bit more may pay off. Cheaper options may seem appealing, but they can compromise quality. Look for a balance between cost and durability.

It’s wise to consult with suppliers about pricing trends. Be prepared for unexpected changes. Factors like shipping costs can add up. Always factor in these additional expenses. Industry experience can help in making a more informed choice.

| Specification | Thickness (mm) | Width (mm) | Length (mm) | Weight (kg) | Approx. Cost ($/ton) |

|---|---|---|---|---|---|

| A36 | 6.0 | 1000 | 2500 | 3000 | 600 |

| S235JR | 8.0 | 1250 | 3000 | 4000 | 580 |

| Q235 | 10.0 | 1500 | 6000 | 9000 | 550 |

| A572 | 12.0 | 2000 | 5000 | 12000 | 570 |