In today’s construction and manufacturing landscape, choosing the right materials is crucial. One option that stands out is Seamless Carbon Steel Pipe. This type of pipe is known for its strength and durability. It is ideal for various applications, from industrial to residential use.

Seamless Carbon Steel Pipe offers many advantages. For instance, it can withstand high pressure and temperature. Its smooth, continuous structure means fewer weak points compared to welded pipes. Users often appreciate its reliability in challenging environments.

However, not all projects may benefit from this material. Factors like cost and specific project requirements should be considered. Evaluating the needs of your project is essential. Seamless Carbon Steel Pipe is a strong choice but may not always be the perfect solution. Careful reflection on these aspects can prevent future regrets.

Seamless carbon steel pipes are increasingly popular in construction. Their benefits are clear. Without welds, these pipes offer superior strength and durability. This feature makes them an excellent choice for high-pressure applications. Construction projects demand reliable materials. Seamless pipes stand up to this challenge well.

They also resist corrosion. This is essential for projects exposed to harsh environments. A seamless pipe will last longer and require less maintenance. Any lapses in material quality can lead to issues. It's essential to inspect pipes before use, even those labeled as seamless.

Tip: Always assess the specific needs of your project. Choose the pipe diameter and wall thickness carefully. Sometimes, budget constraints may tempt shortcuts. Resist this urge; investing in quality pipes pays off in the long run. Weigh all options and consider long-term implications. This choice can significantly affect project integrity and safety.

Seamless carbon steel pipes are widely used across various industries. They find applications in construction, automotive, and oil and gas sectors. Their strength and durability make them an ideal choice for critical applications. Many manufacturers favor these pipes for their ability to withstand high pressure and harsh conditions.

In construction, seamless carbon steel pipes are often used for structural components. They provide excellent support and reliability. In the automotive industry, these pipes play a role in exhaust systems and fuel lines. Their resistance to heat and corrosion ensures longevity in demanding environments.

Tips: When selecting pipes, consider the specific application. Check for compatibility with the fluids they will transport. Regular inspections can prevent costly failures down the line. Understanding the pipes' limits is essential for safety. Proper installation and maintenance are crucial for performance.

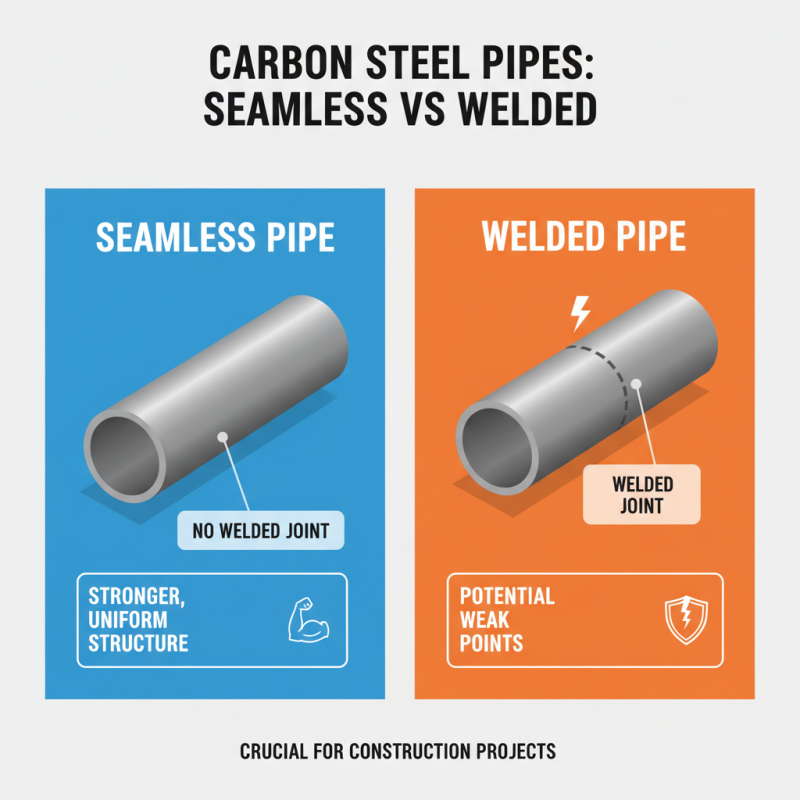

When considering pipes for construction projects, understanding the differences between seamless and welded carbon steel pipes is crucial. Seamless pipes are made from a solid round steel billet. They are processed without any welded joints. This results in a stronger structure, as there are no weak points. On the other hand, welded pipes have a joint where two pieces are fused together. This can create points of potential failure under stress or pressure.

Seamless pipes also have a smooth surface and uniform thickness. This enhances their durability and offers better flow characteristics. Welded pipes may have uneven thickness at the joint. This can lead to corrosion over time. Some argue that welded pipes are easier to produce and more cost-effective. Yet, the trade-off often is a compromise in performance and longevity.

It’s essential to consider your project requirements. The use of seamless pipes can be overkill for lighter applications, potentially leading to unnecessary spending. However, for high-pressure systems, seamless pipes might be the wiser choice. Choosing the right pipe type should align with specific project needs, even when challenges arise in decision-making. Balancing factors like cost, strength, and application is crucial.

When selecting seamless carbon steel pipe for your projects, consider several important factors. The thickness of the pipe can greatly influence its strength and durability. Thicker pipes can withstand higher pressures and are better suited for demanding applications. However, they may also increase the overall weight and cost, which is a key point to reflect on.

Another vital aspect is the material's resistance to corrosion. Some projects require pipes that can endure harsh environments, so choosing a suitable grade is essential. While it may seem tempting to opt for lower-cost options, this could lead to expensive repairs over time. Evaluating your project’s needs carefully can help avoid these pitfalls.

Lastly, think about the intended use. Different industries have unique requirements. For example, oil and gas require high-quality standards. Using pipes that don't meet these specifications can jeopardize safety. Always ensure that the pipe's specifications align with your project’s practical demands.

When considering the maintenance and durability of seamless carbon steel pipe systems, several factors come into play. Seamless carbon steel pipes are renowned for their strength and resistance to high pressure. According to industry reports, these pipes can withstand pressures up to 30,000 psi, making them ideal for various applications. Their structural integrity reduces the likelihood of leaks, which is critical in industries like oil and gas.

However, regular maintenance remains essential. Even the best materials can succumb to corrosion if not properly maintained. Experts recommend inspecting these pipes at least annually. The American Society of Mechanical Engineers (ASME) emphasizes the importance of addressing corrosion early. This can prevent costly downtime and enhance safety.

**Tip:** Regularly check for signs of wear and corrosion. Cleaning the pipes can prolong their life.

Moreover, seamless carbon steel pipes require specific environmental conditions to maximize their durability. While they perform well in many settings, extreme temperatures can impact their longevity. Avoiding exposure to harsh chemicals is also crucial. In situations where chemical exposure isn't avoidable, consider using protective coatings.

**Tip:** Use insulation in extreme conditions to protect your pipes.

Investing in the right maintenance practices ensures seamless carbon steel pipes deliver the durability and reliability you need for your projects.