In the fast-evolving landscape of construction and manufacturing, the selection of the appropriate "Width Carbon Steel Coil" is pivotal for ensuring project success. According to a recent report by the Steel Market Development Institute, the demand for carbon steel coils has surged by 15% over the last year, driven by advancements in automotive and construction industries. This considerable growth underscores the importance of making informed decisions when it comes to choosing the right specifications that meet project requirements.

Industry expert John Smith, a renowned materials engineer, has emphasized, "Selecting the correct width of carbon steel coil can significantly impact not just the structural integrity but also the cost-efficiency of a project." As various sectors like energy and infrastructure continue to expand, understanding the nuances of carbon steel coil widths becomes essential. Selecting the right width not only optimizes material usage but also enhances the overall performance of the final product, making it a critical factor in the planning stages of any endeavor utilizing this versatile material.

In navigating the complexities of selecting width carbon steel coils, project managers and engineers must consider various factors such as industry standards, application-specific needs, and material properties. By aligning these elements with expert insights and industry data, stakeholders can make strategic choices that contribute to the longevity and sustainability of their projects.

When selecting the right width of carbon steel coil for various projects, understanding the specific applications and performance requirements is essential. The width of the coil can significantly impact the material's formability and strength, affecting its suitability for different uses in construction, manufacturing, and other industries. For instance, narrower coils may be preferable for more intricate applications where precision is critical, while wider coils can be advantageous for large-scale production processes, providing efficiency in cutting and handling.

As the global market for carbon steel continues to expand, projected to reach USD 1.80 trillion by 2035, it becomes increasingly important to consider the dimensions of the steel being used. Industries are striving to optimize their production processes, and the right coil width can enhance productivity and reduce waste. Companies often assess their end-product specifications and operational capabilities to choose the appropriate steel coil widths that align with their project goals, underscoring the importance of informed material selection in the evolving steel market.

When selecting the right width of carbon steel coil for your projects, several factors come into play. First, it’s essential to consider the end-use of the product. Different applications, such as automotive, construction, or manufacturing, may require specific widths to ensure optimal performance and fit. Understanding the final application will guide you in choosing a width that meets industry standards and specifications.

Another important factor is the equipment you’ll be using for processing the coil. The capabilities of your machinery, such as cutting or bending tools, may limit or dictate the width options available to you. Additionally, ensure that the coil width aligns with your workflow efficiency; selecting a width that reduces waste and minimizes handling can lead to cost savings.

Tips: Always consult with suppliers about their available widths, as stock and custom options may vary. It’s also beneficial to analyze previous projects to determine width preferences that worked well, ensuring your selection process is informed by real-world experiences. Consider testing samples whenever possible to validate that the chosen width performs effectively for your requirements.

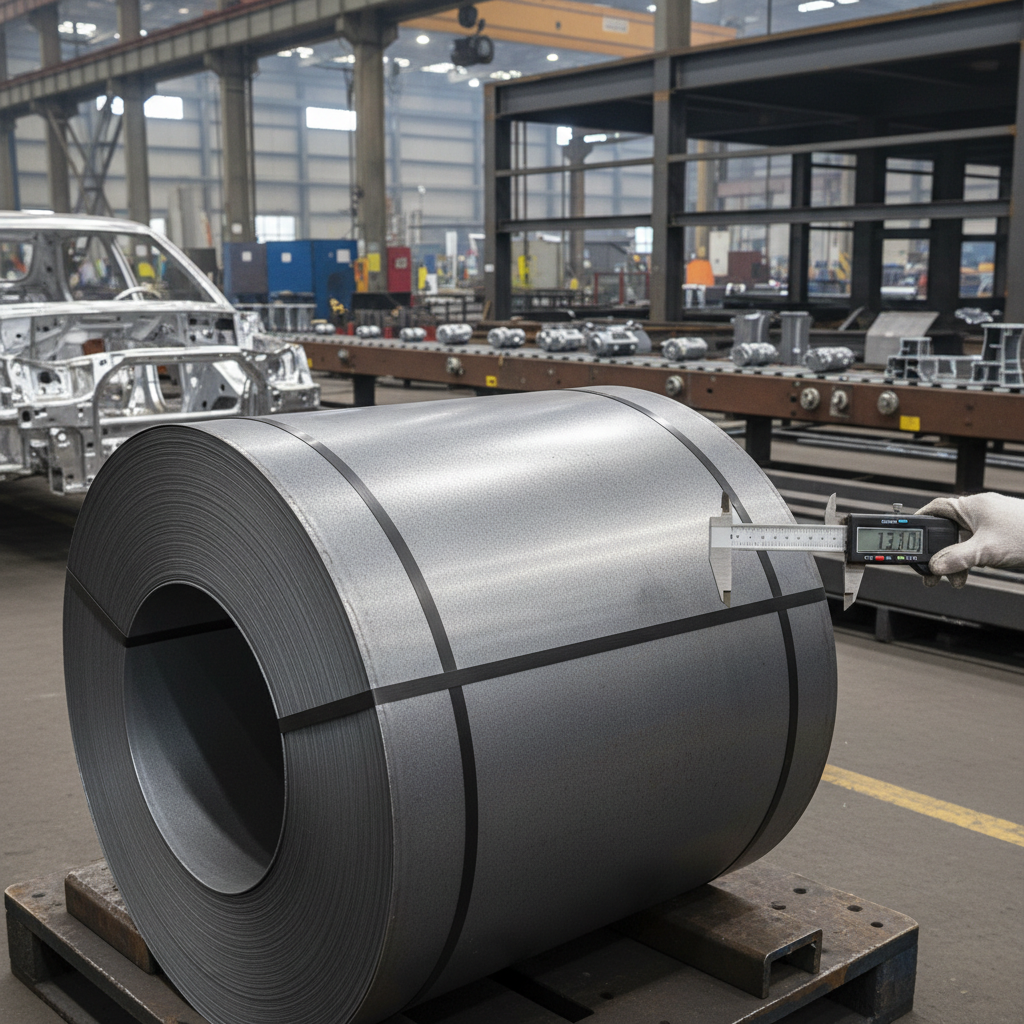

When selecting the appropriate width of carbon steel coil for construction projects, it is essential to measure and assess project requirements meticulously. Accurate measurements are critical, as they directly impact the structural integrity and overall success of a project. This process involves understanding the specific dimensions needed, including evaluating how various widths of steel coil will meet different design specifications and load-bearing demands.

Moreover, integrating advanced geotechnical monitoring solutions is crucial in enhancing oversight in construction projects. Regulatory bodies like OSHA and EPA enforce stringent safety and quality standards, reflecting a growing industry trend towards the adoption of precise measurement tools. As industries increasingly implement digital ultrasonic thickness gauges, the focus on maintaining compliance with safety regulations intensifies. These instruments not only ensure that materials meet quality control expectations but also enable the efficient mapping and assessment of project parameters, fostering a more robust approach to construction management and safety adherence.

When selecting the right width of carbon steel coil for your projects, understanding the efficiency arising from different widths is crucial. As projected, the global carbon steel market is expected to reach USD 1.80 trillion by 2035, highlighting the escalating demand for carbon-based products. A narrower coil width can often enhance manufacturing flexibility and reduce material wastage, aligning with the industry's drive toward more efficient production processes. For instance, narrower coils can be particularly beneficial for applications that require intricate shapes, ensuring better adaptability in automotive component manufacturing.

Moreover, the rising automotive sales directly correlate with an increased need for forged components, further emphasizing the significance of selecting optimal coil widths. As automotive production ramps up, manufacturers must evaluate coil widths that facilitate efficient fabrication of engine parts and other critical components. According to industry reports, the global iron and steel market is projected to grow significantly, reaching USD 1.83 trillion by 2025, indicating not only the high demand but also the competitive nature of material sourcing. In this environment, choosing the correct width of carbon steel coil becomes foundational to enhancing operational efficiency and meeting market demands effectively.

When sourcing carbon steel coils for your projects, it’s crucial to understand the specifications that align with your needs.

Start by identifying the width and thickness required for your application. Different projects may demand varying tolerances and mechanical properties, so it’s essential to collaborate with suppliers who can provide detailed product specifications.

Researching suppliers with a proven track record in the market can significantly influence the quality and delivery time of your order.

Once you have determined your requirements, request samples or test reports from potential suppliers. This will help you assess the quality of the coils and ensure they meet industry standards.

Additionally, establish a clear communication channel with your supplier to address any concerns or special requirements.

By implementing these best practices, you can streamline the ordering process and secure the right width carbon steel coils that will contribute to your project's success.