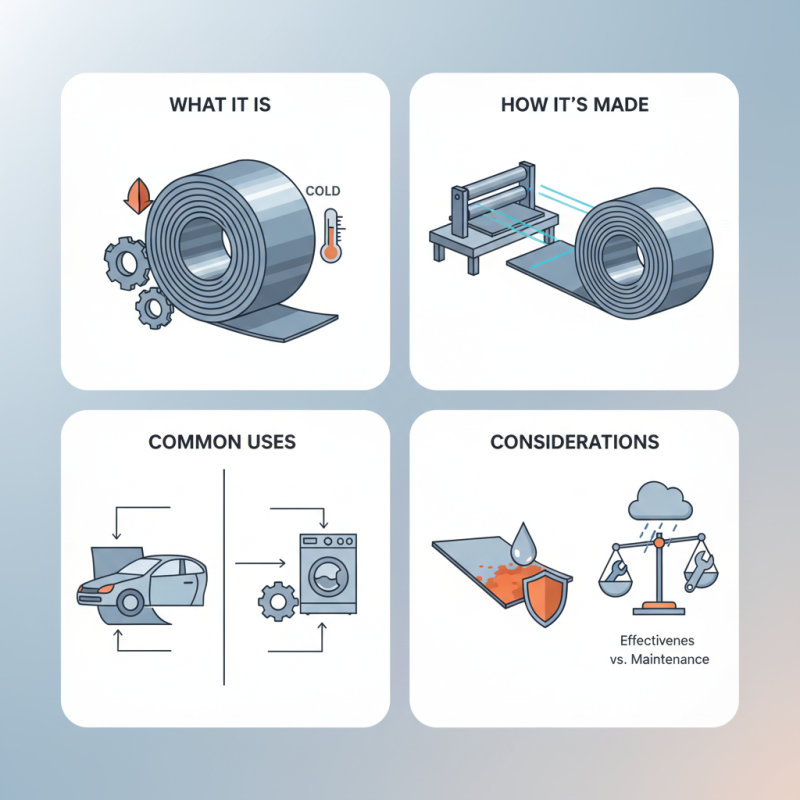

Carbon Steel Cold Rolled Coil is a versatile material widely used in various industries. Its properties make it suitable for applications ranging from automotive to construction. This type of steel is produced by rolling the steel at room temperature, resulting in a smooth and finished surface. Manufacturers often prefer Carbon Steel Cold Rolled Coil for its ability to maintain precise dimensions and high strength.

In the automotive sector, this material is essential for producing components like body panels and frames. Its durability and resistance to wear are crucial in ensuring safety and longevity. Additionally, Carbon Steel Cold Rolled Coil is commonly utilized in machinery and appliance manufacturing. Its uniform thickness allows for better fabrication and assembly.

Despite its advantages, there are challenges to consider. Some may overlook the importance of corrosion protection for Carbon Steel Cold Rolled Coil. Without proper treatment, it can rust easily. Users must be mindful of these factors to fully benefit from this remarkable material. The balance between effectiveness and maintenance is key.

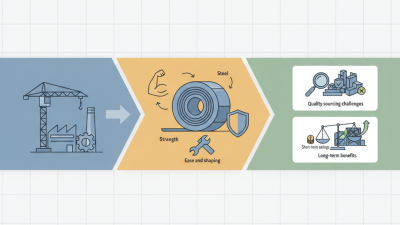

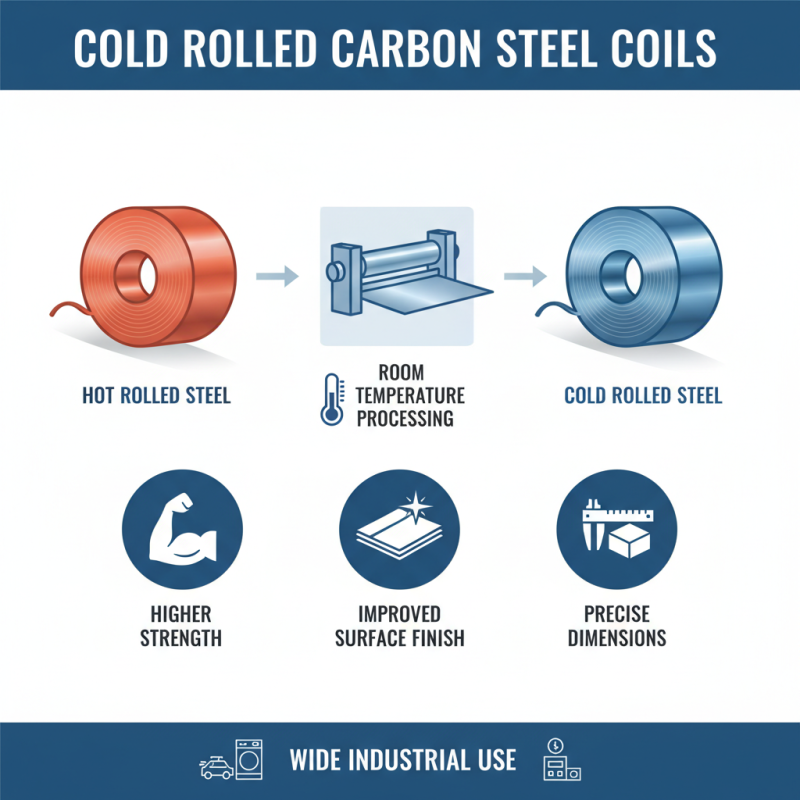

Cold rolled carbon steel coils are widely used in various industries. They are made from hot rolled steel, which is processed at room temperature to enhance certain properties. The result is a product that possesses higher strength and improved surface finish. These coils are smooth, which makes them perfect for applications requiring precise dimensions.

In terms of characteristics, cold rolled steel offers good tensile strength and durability. It has a superior surface finish, which is essential for aesthetic purposes. However, this type of steel can be prone to corrosion. It's crucial to ensure proper coating or treatment to enhance its longevity. Additionally, it’s more difficult to work with than hot rolled steel. This can be a hurdle for some manufacturing processes.

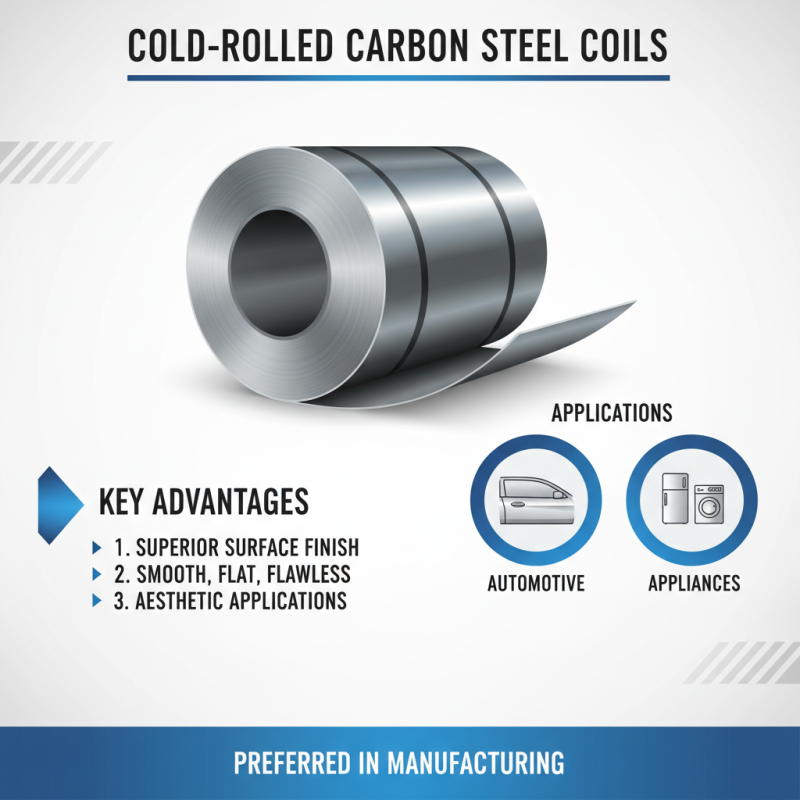

Applications range from automotive parts to appliances. The precision of cold rolled steel is key in these sectors. While its benefits are numerous, the challenges can't be ignored. It's important to weigh the pros and cons before selecting this material for your project. Consider your specific needs and potential downsides.

Cold rolled carbon steel coils undergo a specific manufacturing process that significantly alters their properties. Initially, hot rolled steel slabs are processed further. These slabs are cleaned and then passed through a series of rollers. The rollers apply high pressure. This reduces thickness and enhances surface quality. The temperature is maintained below recrystallization levels. This process strengthens the steel and provides a smooth finish.

After rolling, the coils are subjected to annealing. This step helps relieve stress from the rolling process. Controlling the environment during annealing is crucial. It can affect the final product's characteristics. Additionally, various coatings may be applied for protection. These choices impact corrosion resistance and surface quality. Quality checks are mandatory at this stage, but inconsistencies can occur.

The end product is versatile. Cold rolled coils are used in automotive, construction, and appliance industries. However, challenges do arise. Variability in raw materials can lead to imperfections. Manufacturers must adapt to these challenges. Continuous improvement measures are essential for maintaining quality.

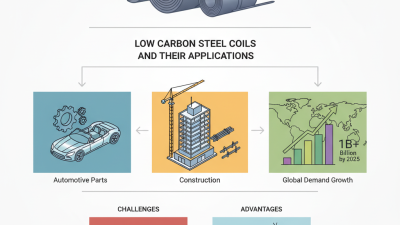

Carbon steel cold rolled coils are essential materials in various industries. They are commonly used for manufacturing automotive parts, appliances, and construction materials due to their strength and durability. These coils feature a smooth surface finish, which enhances their aesthetic appeal and makes them easier to paint or coat.

In the automotive sector, cold rolled coils play a critical role. They are used to produce body panels and structural components. This usage requires precision and a high-quality finish. Additionally, these coils are integral in the production of appliances, such as washing machines and refrigerators. The smooth surface allows for excellent coatings that resist wear and corrosion.

Tips: When selecting carbon steel coils, consider the required thickness and strength. Pay attention to the intended application to ensure optimal performance. Testing samples before large-scale purchasing can prevent wasted materials and costs.

In construction, cold rolled coils are often used for framing and supports. However, the selection process can be tricky. It's important to not overlook the potential for rust or corrosion. Balance between cost and quality is vital. Always assess supplier reliability to avoid future issues.

Cold rolled carbon steel coils are popular in the manufacturing world. They offer specific advantages that make them suitable for various applications. One key advantage is their superior surface finish. This process yields a smooth, flat surface that is often free from imperfections. Manufacturers appreciate this quality for aesthetic applications, such as automotive panels and appliances.

However, cold rolled carbon steel coils also come with notable downsides. Their increased brittleness can lead to cracking during fabrication. This characteristic may limit their use in high-stress applications. Additionally, the production process can be energy-intensive, raising environmental concerns. Some industries may hesitate to adopt these materials due to sustainability issues.

The cost is another factor to consider. While cold rolled steel often offers better performance, the price can vary significantly. Companies need to evaluate whether the benefits outweigh the cost in their specific projects. It's essential to weigh these advantages against potential limitations before making a decision.

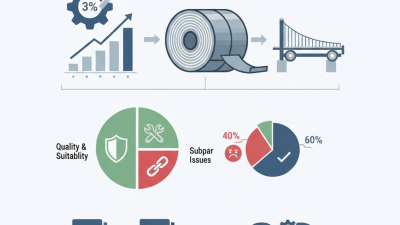

The market for carbon steel cold rolled coils is evolving rapidly. These coils are crucial in various industries, including automotive and construction. Demand is increasing due to a rise in infrastructure projects. However, fluctuations in raw material prices pose challenges. Companies must adapt to these changes to maintain profitability.

Future trends indicate a push for sustainability. Manufacturers are exploring eco-friendly production methods. The demand for high-strength, lightweight materials is also on the rise. Some companies struggle to keep pace with these developments. Continuous innovation is necessary to stay competitive in this transforming landscape.

Despite these advancements, there are concerns. Supply chain disruptions can hinder growth. Companies face pressure to meet rising expectations while managing costs. Balancing these factors demands careful strategy. The future of carbon steel cold rolled coils is bright yet complex.

| Property | Value | Application Areas | Market Trends |

|---|---|---|---|

| Thickness Range | 0.2mm - 6.0mm | Automotive, Construction | Increasing demand in automotive sector |

| Width Range | 1000mm - 2000mm | Home Appliances, Electrical Equipment | Technological advancements in production |

| Surface Finish | Smooth to Slightly Textured | Industrial Machinery, Fabrication | Rising focus on quality finishes |

| Yield Strength | 250 MPa - 700 MPa | Structural Applications, Infrastructure | Sustainability trends driving demand |

| Global Market Growth | 5.2% CAGR (2023-2028) | Metal Fabrication, Shipbuilding | Emerging markets boosting consumption |