Carbon Steel Coil Roll plays a crucial role in various industries. This versatile material is known for its strength and adaptability. According to Dr. Emily Thomas, a leading expert in metallurgy, "The impact of Carbon Steel Coil Roll on manufacturing is profound and often underestimated."

These rolls are commonly used in construction, automotive, and appliance sectors. Their properties make them suitable for producing beams, frames, and other critical components. While their benefits are clear, there are challenges too. Quality control remains a concern, and inconsistencies can lead to product failures.

The production of Carbon Steel Coil Roll involves intricate processes that require precision. Each roll has its specific traits, influencing its final application. Understanding these details is essential for engineers and manufacturers alike. Balancing quality and cost is often a difficult task. As the industry evolves, reflecting on methods is necessary for improvement.

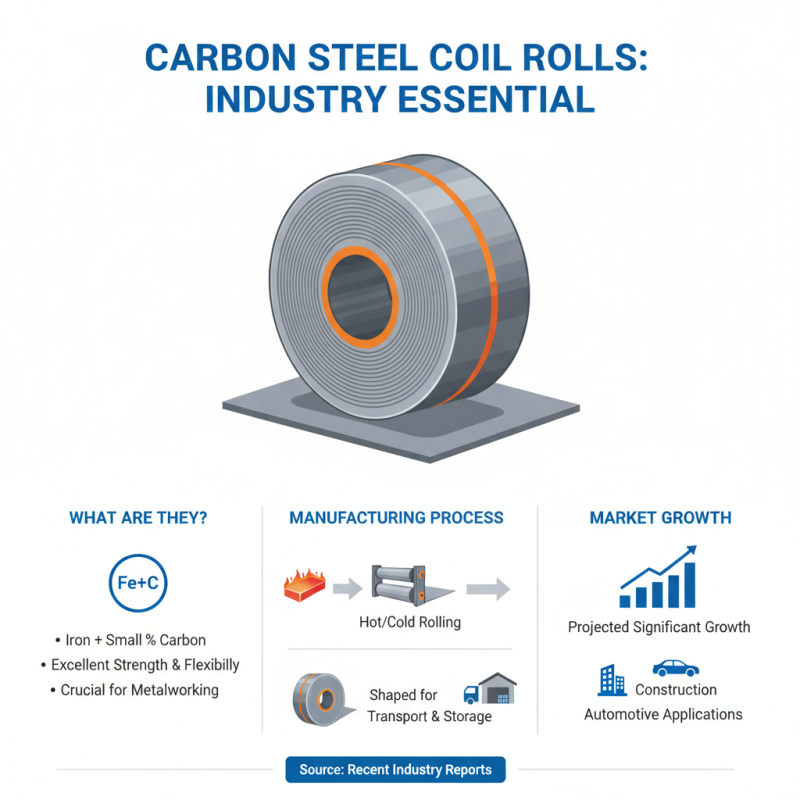

Carbon steel coil rolls are essential products in the metalworking industry. Made from iron with a small percentage of carbon, these coils offer excellent strength and flexibility. The manufacturing process involves hot or cold rolling, where steel is shaped into coils for convenience in transport and storage. According to recent industry reports, the carbon steel market is projected to grow significantly, driven by the demand for construction and automotive applications.

These rolls find various applications, such as building structural frames, automotive parts, and machinery components. Carbon steel's durability makes it ideal for use in challenging environments. Additionally, its cost-effectiveness appeals to manufacturers looking to optimize budgets. However, functioning with carbon steel requires careful handling. Its susceptibility to rust means that proper storage conditions are crucial.

**Tip: Always store carbon steel coils in a dry environment.** This helps prevent oxidation and extends the material's lifespan. Make sure to inspect the coils regularly for signs of wear. While carbon steel offers many benefits, proper care is necessary. Failing to do so can lead to increased costs over time due to material deterioration.

**Tip: Consider the thickness of the carbon steel coil.** Coils come in various thicknesses, impacting their usability in different applications. Thicker coils provide more strength but may be harder to work with. Balancing the coil's weight and your project’s needs is vital for optimal results.

Carbon steel coil rolls are essential in many industries. Their composition mainly includes iron, carbon, and small traces of other elements. Typically, the carbon content ranges from 0.05% to 2.0%, significantly influencing its hardness and strength. Higher carbon levels lead to increased tensile strength but reduced ductility. This trade-off is critical when considering applications.

In terms of properties, carbon steel coils exhibit excellent machinability and weldability. According to the American Iron and Steel Institute (AISI), these materials offer diverse grades, each tailored for specific applications. For instance, grades 1018 and 1045 are popular in manufacturing due to their balance of strength and ease of work. However, the susceptibility to corrosion presents a notable challenge. Despite these downsides, advancements in treatments and coatings aim to enhance durability.

Industries like construction and automotive prioritize these coils due to their cost-effectiveness and mechanical properties. They are favored for components like frames and reinforcements. However, the reliance on carbon steel has raised discussions about environmental impact. The pursuit of sustainable alternatives is ongoing amidst concerns over carbon footprint.

Carbon steel coil production involves several key manufacturing processes that ensure high-quality materials. The process typically begins with the melting of raw steel in an electric arc furnace. This allows for precise control over the chemical composition of the steel. After melting, the steel is cast into slabs. These slabs are then hot-rolled to reduce thickness. Hot rolling also enhances ductility and strength.

Once the desired thickness is achieved, the steel enters the cold rolling phase. Cold rolling further refines the surface and dimensions. This step can also introduce challenges. It's important to monitor the temperature and speed carefully. An incorrect setting can lead to defects. These defects can affect the final usage of the carbon steel coils.

The final step often involves applying a protective coating to prevent rust. Despite advancements, there are still issues to address, such as inconsistencies in thickness or surface quality. Continuous improvement is essential in this competitive field. Each phase of production offers learning opportunities. These reflections can lead to better processes and end products in the future.

This chart illustrates the production volume of different types of carbon steel coils. The data shows that hot-rolled steel has the highest production volume, followed by cold-rolled and galvanized varieties. These insights are essential for understanding the manufacturing landscape of carbon steel coils.

Carbon steel coil is used across many industries due to its versatility and strength. One common application is in construction. Builders use carbon steel for beams, columns, and reinforcements. According to the World Steel Association, around 50% of all steel is used in construction projects. This shows how essential carbon steel is for structural integrity.

Another significant use is in the automotive sector. Carbon steel coils are critical for manufacturing car bodies and components. The automotive industry accounted for approximately 15% of global steel demand in 2022. Using carbon steel ensures durability and efficiency in vehicles, but it also raises concerns about weight and fuel efficiency. Hence, manufacturers are exploring lighter materials while maintaining strength.

Moreover, the packaging industry relies on carbon steel for creating durable containers. These coils can be transformed into cans and other packaging solutions. In 2021, the global steel packaging market was valued at $82 billion. This category often faces sustainability challenges. The carbon footprint of producing steel is another issue to consider. As industries evolve, the need for environmentally friendly practices is rising.

| Industry | Common Applications | Specifications | Benefits |

|---|---|---|---|

| Construction | Reinforcement bars, Structural steel | Grade S235, S275 | High strength, Cost-effective |

| Automotive | Body panels, Frame components | Grade S355 | Lightweight, Durable |

| Manufacturing | Machinery parts, Tools | Grade C45 | Machinability, Versatility |

| Oil & Gas | Pipes, Tubing | API 5L Grade B | Corrosion resistant, High pressure capacity |

| Aerospace | Structural components, Fasteners | 4130 Alloy | Lightweight, Strong |

Carbon steel coils are crucial in many industries. Their versatility makes them a popular choice for construction, manufacturing, and automotive applications. As demand for robust materials continues, the market for carbon steel coils is evolving.

Recent trends highlight a growing emphasis on sustainability. Manufacturers are exploring eco-friendly production methods. This shift could reshape the industry in the coming years. However, the pressure to implement these changes often faces practical challenges. Not all companies have the resources to transition quickly.

The market outlook remains optimistic, but volatility is apparent. Global demand fluctuates based on economic conditions. Prices can vary widely depending on supply chain elements. Companies must adapt to these changes or risk obsolescence. Investing in innovative processes could lead to long-term advantages. Yet, the path forward requires strategic thinking and flexibility in operations.