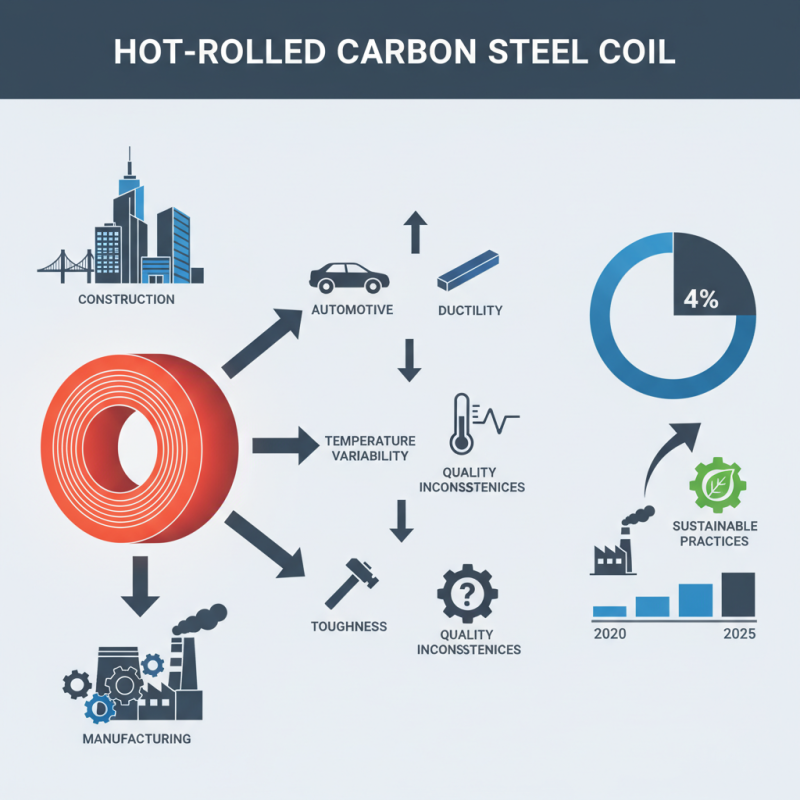

Carbon Steel Coil Hot Rolled plays a critical role in various industries. This material is essential for construction, automotive, and manufacturing sectors. According to a report by Grand View Research, the global demand for hot-rolled carbon steel is expected to reach 1.6 billion metric tons by 2025. This significant growth reflects the increasing utilization of carbon steel coils in structural applications.

The characteristics of Carbon Steel Coil Hot Rolled contribute to its importance. Hot rolling enhances ductility and toughness, making the material ideal for demanding environments. However, it also presents challenges. For instance, the mechanical properties can vary based on temperature and processing techniques. Furthermore, inconsistencies in quality may arise from production methods. This variability necessitates a thorough examination of suppliers and materials before committing to large orders.

Environmental concerns are also prevalent. The steel industry is one of the largest contributors to carbon emissions. As highlighted by the World Steel Association, carbon steel production accounts for 4% of global CO2 emissions. This awareness is pushing industries towards more sustainable practices. Emphasizing the need for innovation in production methods is crucial for reducing the ecological footprint of Carbon Steel Coil Hot Rolled.

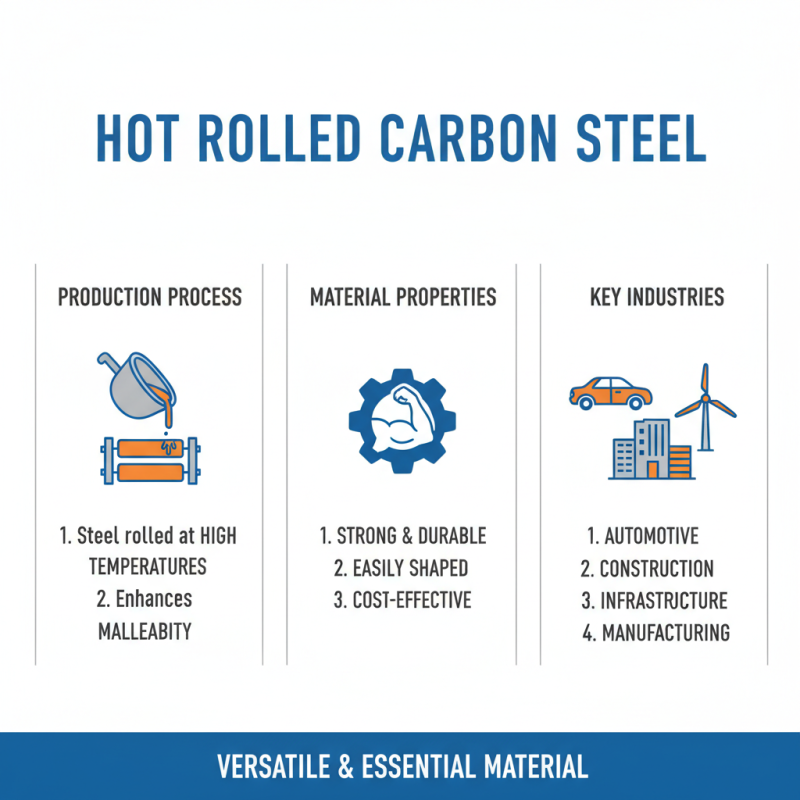

Carbon steel coil hot rolled is a type of steel product derived from high temperatures. The process involves heating steel above its recrystallization temperature, which makes it more malleable. This allows the material to be shaped into coils through rolling. The result is a steel coil that is flexible and easy to work with.

One of the main characteristics of hot rolled carbon steel is its scalability. It can be produced in large quantities, making it cost-effective. The surface finish may not be smooth or perfect, which can be a drawback for some applications. However, this rough surface can allow for better adhesion when used in welding or coating.

Hot rolled carbon steel coils are widely used in construction and automotive industries. They are often used for structural beams, automotive parts, and other heavy-duty applications. Despite its advantages, it’s important to recognize that quality can vary. Manufacturing inconsistencies may lead to defects that need careful inspection.

The manufacturing process of hot rolled carbon steel coils involves several key stages. Initially, raw steel is heated to a high temperature, typically around 1,480°F. This intense heat makes the steel malleable. The molten steel is then poured into molds to form slabs. These slabs undergo a series of rolling operations, where they are passed through large rollers. This process reduces their thickness and shapes them into coils.

Once shaped, these coils go through cooling processes. After cooling, they are often pickled in acid to remove imperfections. Careful inspection is crucial at this stage. Small defects can impact the final product's quality. Manufacturers must continually assess their processes. Not every batch meets the required standards, prompting the need for constant adjustments.

The significance of hot rolled carbon steel coils lies in their versatility. They are used in various applications, from construction to automotive parts. However, the manufacturing process can lead to inconsistencies. Variations in temperature and pressure during rolling can affect coil properties. Awareness of these factors is essential. It allows manufacturers to produce better-quality steel. Balancing efficiency and quality remains a challenge.

Hot rolled carbon steel coils find extensive use across various industries. They are often used in the construction sector. Beams, columns, and steel frames benefit from the strength of these materials. Their formability allows for easy shaping and manipulation. As a result, many buildings and bridges utilize hot rolled carbon steel.

In manufacturing, hot rolled carbon steel coils serve multiple purposes. They are found in automotive production, where components require durability and flexibility. Additionally, manufacturing appliances often relies on this type of steel. It provides the right balance of hardness and ductility. This versatility makes it a go-to choice for factories and workshops.

Despite its advantages, hot rolled carbon steel is not without challenges. The surface can be rough and may require finishing processes. This can add to production time and costs. Moreover, the material is susceptible to rust if not coated properly. Such drawbacks remind industries to consider both the benefits and the limitations of using hot rolled carbon steel.

Hot rolled carbon steel is a vital material in various industries. It is produced by rolling steel at high temperatures, which enhances its malleability. This process results in a product that is strong yet easily shaped. Many industries rely on hot rolled carbon steel for its strength and cost-effectiveness.

One of the main benefits is its durability. Hot rolled carbon steel can withstand heavy loads and harsh conditions. This quality makes it ideal for construction and manufacturing. It also supports structural integrity in buildings and bridges. The ability to customize shapes and sizes further increases its applicability.

Tips: Always consider the specific requirements of your project when choosing materials. Evaluate the environmental conditions the steel will face. This can help avoid costly mistakes down the line. Additionally, remember that imperfections can occur during production. Regular quality checks can prevent future issues.

Hot rolled carbon steel plays a vital role in modern construction. Its strength and durability make it a popular choice for building structures. Unlike cold rolled steel, hot rolled steel is shaped at high temperatures. This method allows for greater flexibility in forming larger sections, which is essential for beams and columns.

Construction workers rely on hot rolled carbon steel for its ability to absorb shock and stress. It’s often used in bridges and high-rise buildings. The steel's resilience ensures that structures can withstand harsh weather and heavy loads. However, the finishing may not always be perfect. Some imperfections might require additional treatment or adjustments.

**Tip**: When choosing hot rolled carbon steel, consider the application. Evaluate the environment and load requirements. Selecting the right thickness can enhance performance.

Another factor to ponder is the welding process. Hot rolled steel could be more challenging to weld due to its scale. This may lead to weaker joints if not properly handled.

**Tip**: Always inspect the welding quality. A small flaw can lead to safety issues down the line. Regular checks during construction can save significant costs later.

| Property | Description | Importance in Construction |

|---|---|---|

| Tensile Strength | A measure of the force required to pull something to the point of failure | Essential for structural integrity of buildings and bridges |

| Ductility | Ability of the material to deform under tensile stress | Allows for flexibility in construction and reduces risks of sudden failures |

| Cost-Effectiveness | Lower production costs compared to other materials like stainless steel | Helps in maintaining budget constraints in large construction projects |

| Weldability | Easily welded with various welding techniques | Facilitates assembly of structural components on site |

| Versatility | Can be used for a variety of applications including beams, bars, and sheets | Suitable for diverse construction requirements and environments |