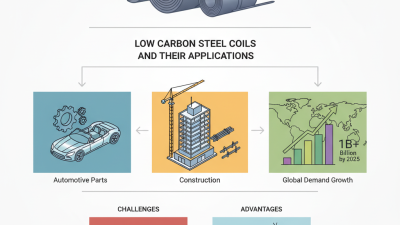

Carbon Steel Coil Cold Roll is a critical component in today's manufacturing landscape. According to a recent industry report by Smith & Associates, the global cold rolled steel market is projected to reach over $150 billion by 2025. This growth reflects the increasing demand for durable, high-quality materials across various sectors. Carbon Steel Coil Cold Roll is renowned for its versatility and strength, making it ideal for automotive, construction, and appliance industries.

Expert Samantha Lee, a leading analyst at Steel Insights, emphasizes the importance of this material. She states, “Carbon Steel Coil Cold Roll is indispensable for modern applications due to its exceptional properties.” This highlights the material's significance in producing reliable products for daily use. Despite its advantages, the manufacturing process faces challenges. Quality control issues can arise, and there are environmental concerns surrounding the production of steel. Addressing these points is critical for sustainable industry growth.

In conclusion, Carbon Steel Coil Cold Roll stands out in modern manufacturing. Yet, the industry must navigate its challenges responsibly. Balancing innovation and sustainability remains an ongoing concern for manufacturers today.

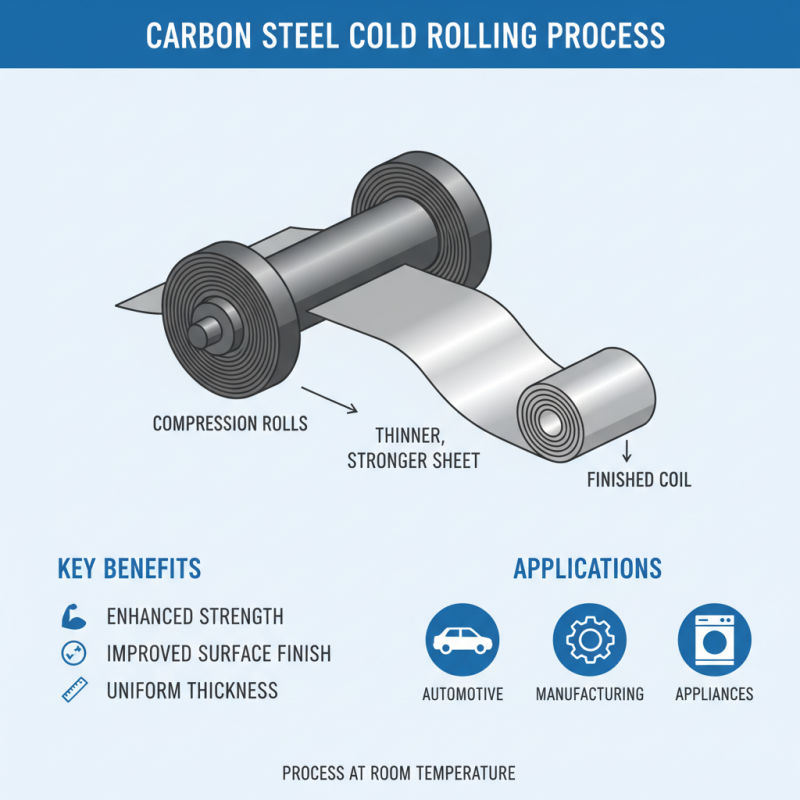

Carbon steel coil cold roll refers to a manufacturing process where sheets of carbon steel are compressed at room temperature. This technique enhances the steel's strength and surface finish. The process is vital for producing thinner, more uniform sheets, which are essential in various industries.

The applications of cold-rolled carbon steel coils are extensive. They are commonly used in automotive manufacturing, construction, and appliances. For instance, in car production, they are utilized for body panels and structural components. However, imperfections can occur during the rolling process, leading to surface blemishes or variations in thickness. These issues need careful consideration in production quality control.

Cold-rolling also allows for customization in dimensions and properties. Engineers can specify unique steel grades for specific applications. Despite its versatility, it is crucial to remember that colder rolling makes steel more susceptible to corrosion. Thus, proper protective measures are necessary. The balance between durability and cost is a constant challenge for manufacturers.

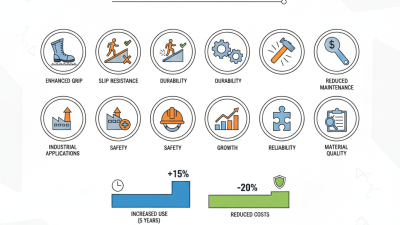

Carbon steel coil cold roll is vital in various industries. It exhibits unique characteristics that make it highly valued in manufacturing. One main feature is its strength. Cold-rolled carbon steel has a yield strength of around 250 MPa to 400 MPa. This high strength-to-weight ratio enables its use in structural applications.

Another key characteristic is surface finish. Cold rolling enhances the surface quality, making it smoother than hot-rolled steel. This is crucial for products that require precise aesthetics or functionality. Additionally, it has improved dimensional tolerance, which is essential for components needing exact measurements. According to industry reports, cold-rolled steel accounts for approximately 20% of the total steel production globally.

Tip: When selecting cold-rolled carbon steel, consider your project's specific strength requirements. Not all grades offer the same durability.

Flexibility in application is another trait. Carbon steel coil cold roll is used in everything from automotive components to furniture. However, it's essential to note that this type of steel can be prone to corrosion. Proper maintenance and coatings are often needed. Balancing strength and vulnerability is a common challenge in the industry.

Cold rolled carbon steel coils undergo a specialized manufacturing process. This technique transforms hot rolled steel into a thinner and smoother product. The cold rolling process involves feeding hot rolled steel through rollers at room temperature. The result is a product with improved dimensional accuracy.

During production, the steel is often subjected to several passes through the rollers. This can lead to variations in thickness and surface quality, which manufacturers must carefully monitor. The surface finish can sometimes be less than perfect, requiring further treatments. This is a crucial aspect of the cold rolling process, as it directly impacts the material's performance in various applications.

After shaping, the coils are tempered and treated to enhance properties like hardness and strength. Some manufacturers face challenges, such as maintaining uniformity across coils. In some cases, temperature fluctuations can affect the final product's quality. Attention to detail is vital, as even minor imperfections can lead to significant issues in the final applications, like automotive parts or construction materials.

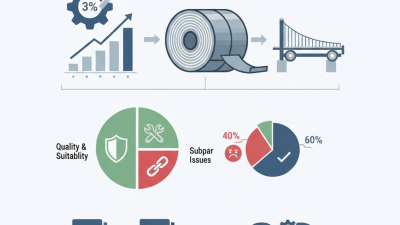

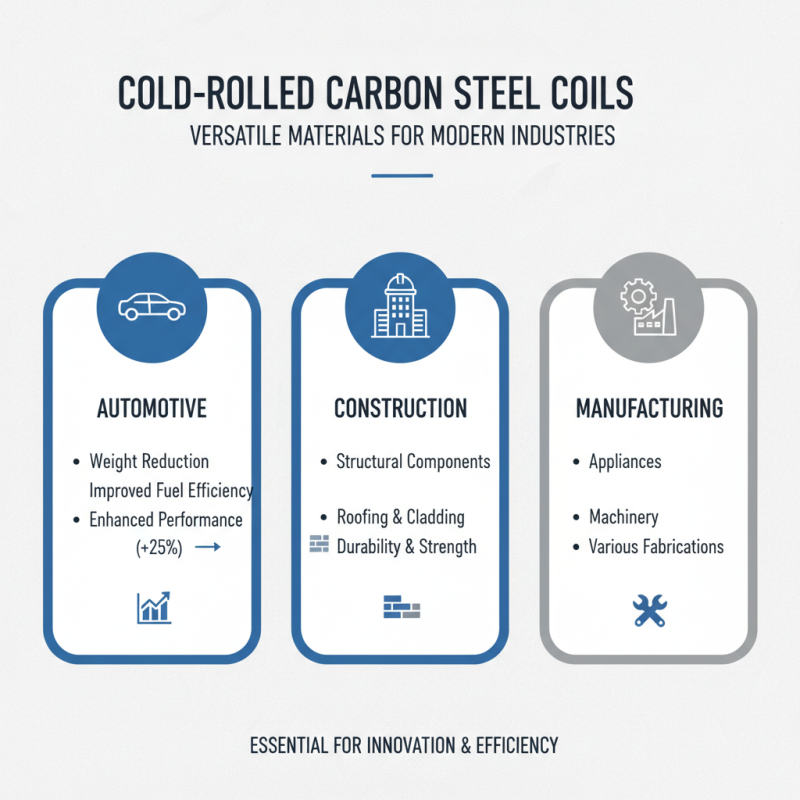

This chart illustrates the various applications of cold rolled carbon steel coils by percentage. The automotive industry is the largest user, followed by construction, while shipping has the least percentage of application.

Cold rolled carbon steel coils are versatile materials used in various industries. Their applications span automotive, construction, and manufacturing sectors. In the automotive industry, these coils contribute to weight reduction, thus improving fuel efficiency. Studies show that using lightweight materials can enhance vehicle performance by up to 25%.

In construction, cold rolled carbon steel is popular for fabricated frames and structural components. According to industry reports, this steel provides strength and durability while remaining cost-effective. Builders appreciate the material's ability to be easily shaped into complex designs. However, it's essential to consider corrosion protection, as untreated coils may suffer in harsh environments.

Manufacturers also utilize these materials for appliances and equipment. Cold rolled carbon steel offers excellent surface finish and dimensional accuracy. Reports indicate an increase in demand for such materials, but challenges remain. Quality control is often overlooked, leading to defects. Industries must prioritize inspections to ensure product reliability.

Carbon steel coil cold roll is produced by passing steel through rollers at room temperature. This process enhances the steel's strength, surface finish, and dimensional accuracy. There are various industry standards and specifications governing the quality and characteristics of carbon steel coils. Adhering to these standards ensures that the products meet safety and performance requirements.

The ASTM A1008 standard is one such specification for cold-rolled carbon steel sheets. It outlines chemical and mechanical requirements. Another standard, ASTM A1011, applies to hot-rolled sheets but often overlaps with cold-rolled applications. These standards dictate thickness, surface quality, and mechanical properties. Notably, while the specifications exist, compliance can sometimes be lax. This raises concerns about the consistency and reliability of the materials delivered to the market.

Manufacturers are challenged to maintain quality control while keeping production costs low. Each batch of steel can have variations. These discrepancies may affect the final product's integrity. It’s important to regularly review and update practices to adhere to the latest standards. Continuous improvement should be a goal, despite existing challenges in the industry.