When considering materials for construction and manufacturing, choosing the right Steel Plate Carbon Steel Coil is crucial. This material is known for its strength and versatility. According to the World Steel Association, carbon steel demand has seen a steady increase of 3% annually over the last five years. As industries adapt to modern needs, the demand for high-quality coils remains significant.

However, not all suppliers provide the same quality. Reports indicate that 40% of buyers have faced issues with subpar quality. Selecting the right supplier is essential to ensure durability and cost-effectiveness in projects. Many industries, from automotive to construction, rely heavily on these coils. The versatility of Steel Plate Carbon Steel Coil allows it to support various applications while maintaining structural integrity.

Choosing the best options should reflect both quality and suitability for specific tasks. Some projects may require thicker plates, while others may benefit from lighter coils. Being attentive to these specifications can prevent costly mistakes later. Understanding how to select the most effective Steel Plate Carbon Steel Coil is a skill that all industry professionals need to develop.

When selecting carbon steel coils for projects, it’s essential to understand the available types. Carbon steel coils are categorized mainly into hot-rolled, cold-rolled, and galvanized options.

Hot-rolled coils are ideal for heavy-duty applications. They are formed at high temperatures, offering excellent formability. Cold-rolled coils, on the other hand, provide a smoother finish and tighter tolerances, suitable for precision work. Galvanized coils are coated for corrosion resistance, making them popular for outdoor projects.

According to industry reports, the demand for these materials is on the rise. In fact, the global market for carbon steel is projected to grow at a CAGR of 5% through 2026. This growth signals that investing in high-quality carbon steel coils can be beneficial for both short-term and long-term projects.

Tip: Always check the specifications of your chosen coil. The thickness, width, and chemical composition matter. Choosing the wrong specifications may lead to complications and increased costs. Sometimes, it’s easy to overlook these details, but they significantly influence the project's success. These small errors can derail progress.

Particularly in customized projects, metering and cutting become crucial. Make sure to double-check measurements. A small mistake in dimensions can escalate into larger issues down the line. Errors can be costly. Hence, precise planning is imperative.

When choosing steel plate options, several key factors come into play. The thickness of the plate affects its strength and application. Thinner plates are lightweight but less durable. Thicker plates provide more strength, but they are heavier and more difficult to maneuver. Assessing your project's needs can help you determine the right thickness.

Consider the steel's finish as well. Some finishes offer better corrosion resistance than others. A polished finish may be ideal for aesthetic purposes. Hot-rolled steel offers a more rugged look but may require extra protection. Each finish comes with pros and cons that must be carefully weighed.

Pay attention to the steel's yield strength too. This is crucial for projects that face heavy loads. Lower yield strength may lead to unexpected failures. Testing the steel before use can prevent future issues. Overall, understanding these details enhances project outcomes significantly.

When selecting carbon steel coil suppliers, one must consider various aspects. The quality of the steel is paramount. It affects the longevity and performance of your projects. Different suppliers offer a range of standards and grades. Some may specialize in heavy-duty applications while others cater to lighter tasks. Evaluating these distinctions can save you headaches later.

Another crucial factor is pricing. Often, lower prices can indicate compromised quality. It’s vital to assess the balance between cost and reliability. Not all suppliers use the same sourcing methods. Some prioritize sustainability, while others focus purely on production speed. Researching these practices can reveal a lot about a supplier’s reliability.

Customer service also plays a significant role. Suppliers that provide timely support can be invaluable during urgent projects. However, many businesses struggle with response times. This inconsistency can lead to delays and frustration. Before making a selection, seek feedback from other customers. Their experiences can guide you to make a more informed choice.

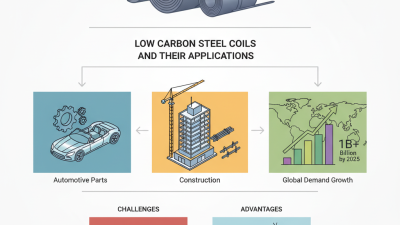

Steel plates are vital in many industries. They find applications in construction, shipbuilding, automotive, and energy sectors. According to industry reports, the global steel plate market is projected to reach $200 billion by 2025. This demand stems from the diverse uses of steel plates, such as structural elements in buildings and vehicles.

In construction, steel plates provide strength and durability. They are used for beams, columns, and even as flooring systems. Their ability to withstand heavy loads makes them ideal for skyscrapers. In manufacturing, companies often employ steel plates in machinery and equipment. The automotive industry relies heavily on these materials for car frames and body panels. A recent survey indicated that over 50% of vehicle weight comes from steel components.

However, there are challenges. Some projects struggle with sourcing high-quality materials. There are frequent reports of inconsistencies in steel plate thickness and quality. Such issues can lead to project delays and increased costs. Thus, careful selection of suppliers is critical. Stakeholders must ensure compliance with standards and specifications. This attention to detail can mitigate risks and enhance project outcomes, making it essential for project success.

Carbon steel coils are popular in various projects due to their strength and flexibility. However, they require proper maintenance and care to ensure longevity. Regular inspections are critical. Check for rust or corrosion early. If found, treat it immediately. Proper storage is also essential. Keep coils in a dry environment to prevent moisture accumulation.

Tips for maintaining carbon steel coils:

- Use protective oils to prevent rust.

- Clean dirt and debris regularly.

- Take care when handling to prevent scratches.

Improper care can lead to significant issues. Neglecting these aspects may shorten the lifespan of your coils. Additionally, always note that even small scratches can lead to bigger problems later. It’s vital to create a maintenance routine, even if it seems tedious. Remember, attention to detail pays off in the long run.