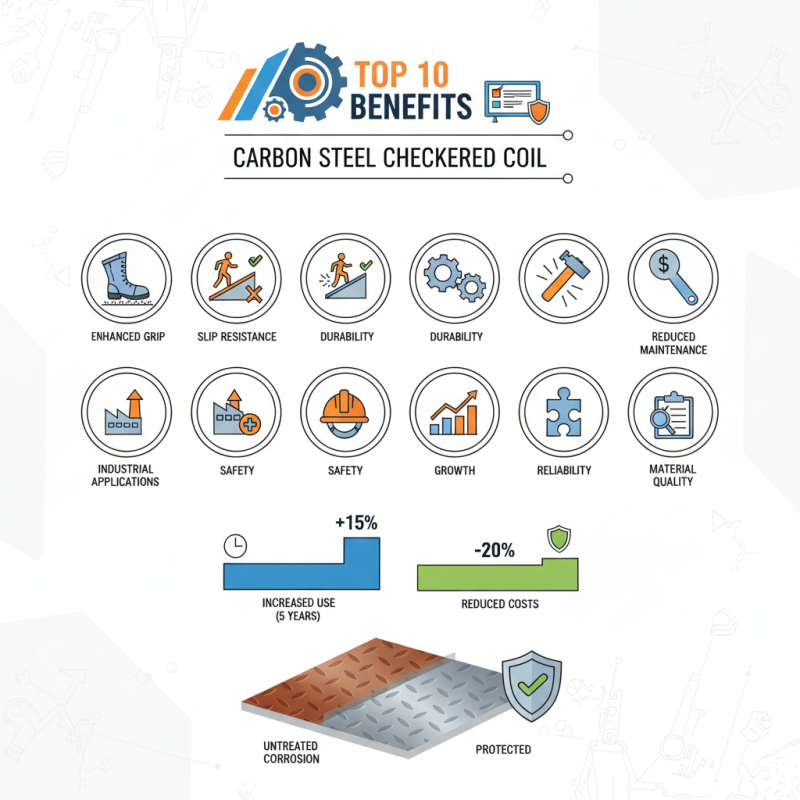

Carbon Steel Checkered Coil has become increasingly popular in various industrial applications. Its unique properties offer practical advantages that enhance project outcomes. According to recent industry reports, the use of carbon steel products has risen by over 15% in the last five years. This growth reflects a broader trend towards durable and reliable materials in construction and manufacturing.

The checkered pattern provides enhanced grip and slip resistance. This is crucial in areas where safety is a priority, like walkways and ramps. Furthermore, carbon steel offers excellent resistance to wear and impact. A study noted that structures using these coils reduced maintenance costs by nearly 20%. Nevertheless, careful consideration is needed regarding corrosion protection, as untreated surfaces can lead to deterioration over time.

While the benefits are significant, challenges remain in sourcing high-quality materials. The market is flooded with options, and not all provide the same level of performance. It’s essential to evaluate suppliers diligently. In conclusion, the Carbon Steel Checkered Coil is an invaluable asset. Its merits warrant deeper exploration for optimal project execution.

Carbon steel checkered coil offers significant advantages in construction projects. Its unique surface pattern provides increased traction. This is critical for safety on walkways and ramps. The raised patterns help prevent slips. Workers can feel more secure on these surfaces.

Another benefit is its durability. Carbon steel is known for its strength. It withstands heavy loads and harsh conditions. Projects exposed to the elements can rely on it. However, it does require proper maintenance to prevent rust. Regular inspections should be a part of the plan.

Cost-effectiveness is another notable aspect. While initial prices may vary, long-term savings are achievable. The material’s longevity means fewer replacements. This can lead to budget efficiencies over time. Yet, choosing the right suppliers remains a challenge. Ensuring quality can sometimes feel overwhelming.

Carbon steel checkered coils are gaining popularity due to their enhanced durability and strength. This material offers a reliable solution for various industrial applications. The checkered pattern provides better grip, making it ideal for flooring and ramp uses. According to industry reports, carbon steel has a tensile strength ranging from 400 to 600 MPa, significantly outperforming other materials like aluminum and plastic.

One key benefit is corrosion resistance. Carbon steel, when properly treated, can withstand harsh environments. This feature is crucial for projects in construction and transportation. Research indicates that coated or galvanized surfaces can extend the life of carbon steel by up to 50%. During rainy conditions, this resistance proves vital, as slip hazards are minimized.

Tips: Focus on selecting the right thickness for your project. Thicker coils offer more stability but may be heavier. Also, consider the finish; a proper coating can enhance both aesthetics and longevity. Regular inspections will ensure no hidden issues affect performance. Remember, the balance between cost and quality often demands careful planning.

| Benefit | Description | Applications |

|---|---|---|

| Enhanced Durability | Carbon steel checkered coils provide excellent strength and resistance to wear and tear. | Construction, flooring, storage containers |

| Lightweight | Despite their strength, they are significantly lighter than other metal options. | Transportation, automotive parts |

| Cost-Effective | Offers a balance of performance and price, making it affordable for various projects. | Industrial applications, manufacturing |

| Anti-Slip Surface | The checkered pattern provides traction, improving safety in walkways and vehicles. | Staircases, ramps, and flooring |

| Versatile Use | Adaptable for various industries and applications due to its properties. | General construction, automotive, machinery |

| Corrosion Resistance | Depending on the finish, can be treated to resist rust and chemical exposure. | Outdoor structures, marine applications |

| Easy Fabrication | Can be easily cut, welded, and shaped to fit specific project needs. | Custom projects, repairs |

| Aesthetic Appeal | The checkered design provides an appealing look for various displays. | Retail displays, modern architecture |

| Temperature Resistance | Maintains performance under varying environmental conditions. | Heavy machinery, outdoor applications |

| Sustainability | Recyclable material allows for sustainable manufacturing practices. | Building materials, eco-friendly projects |

Carbon steel checkered coils offer significant cost-effectiveness in manufacturing. Their unique textured surface enhances grip and slipping resistance. This characteristic reduces accidents and improves safety in various applications. Projects benefit from reduced material waste, as these coils are durable and easy to handle.

Additionally, carbon steel is typically cheaper than other metals. It combines strength and resilience, which makes it an attractive option for budget-conscious projects. However, it’s essential to consider corrosion resistance. Without proper treatment, carbon steel can rust, leading to increased maintenance costs over time. Striking a balance between initial savings and long-term durability is crucial.

Using carbon steel checkered coils can streamline production processes. They are easy to cut and shape, offering versatility. Yet, one should reflect on their environmental impact. The production process can have a significant carbon footprint, which raises sustainability concerns. Careful sourcing and responsible manufacturing practices are vital for minimizing these effects.

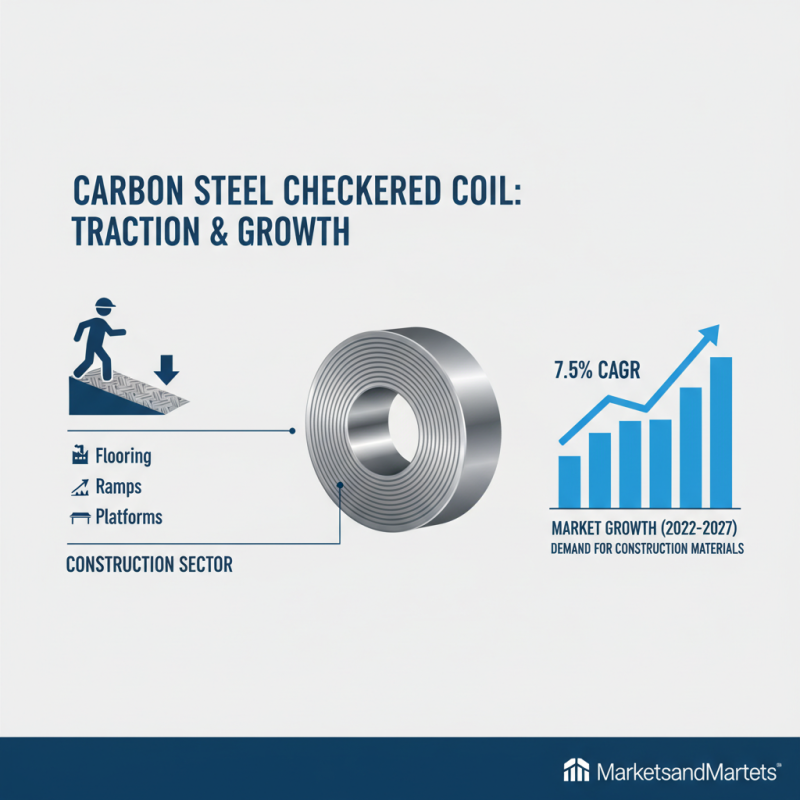

Carbon steel checkered coil has gained traction across various industries due to its unique properties. In the construction sector, it is frequently utilized for flooring, ramps, and platforms. The textured surface provides excellent traction, decreasing the likelihood of slips and falls. According to a report by MarketsandMarkets, the demand for construction materials, including carbon steel, is expected to grow at a CAGR of 7.5% from 2022 to 2027.

In the automotive industry, carbon steel checkered coils serve multiple purposes. They are often used in the production of automotive parts that require strength and durability. The material's resistance to wear and tear makes it a reliable choice. However, manufacturers should remain cautious about corrosion, which can compromise its integrity over time. The global automotive steel market is projected to reach $216 billion by 2026, indicating substantial growth and increasing reliance on materials like carbon steel.

Oil and gas applications also benefit from carbon steel checkered coils. They are used for walkways and scaffolding in rig operations. The resilience of carbon steel to extreme conditions is vital. Yet, this industry must address the environmental impact of using such materials. Reports indicate that 25% of global steel production contributes to carbon emissions. As industries evolve, balancing performance and sustainability will be crucial for future developments.

Maintaining carbon steel checkered coils is essential for their longevity and performance. Regular inspections are vital. Look for corrosion or scratches that may weaken the material. A study showed that routine maintenance can extend the lifespan of carbon steel by up to 30%. Simple cleaning with mild detergents and water helps remove dirt. This prevents buildup that can lead to rust.

Proper storage is equally important. Keep the coils in a dry place. Humidity can lead to oxidation. In fact, reports indicate that environments with 60% humidity can begin to cause rust in as little as 30 days. Make sure the storage area has good ventilation. This reduces moisture accumulation. Remember, prevention is better than repair.

Using protective coatings is also beneficial. These coatings can add a layer of defense against environmental factors. However, these coatings can wear off over time. Regular checks ensure you can reapply them as needed. This strategy can further enhance resistance to wear and tear. Avoid neglecting these maintenance steps. Ignoring them can lead to costly repairs down the line.